We are discussing a way to precisely measure PT100 (variable resistance) using a MSP430 with 24bit sigma-delta differential ADCs without having a precision source of current or voltage.

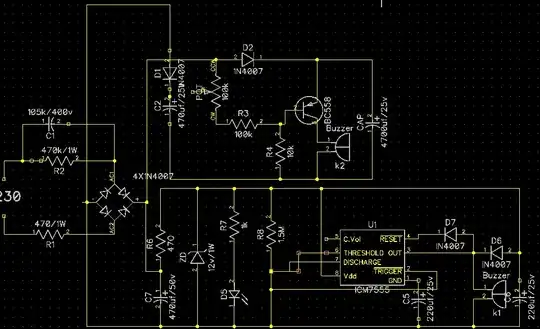

We came up with this solution:

The way we want to do this is: measure voltage on (known) R2, calculate current then apply this calculated current to voltage measurement on TH1 to get resistance (and therefore, temperature).

R8 is there to limit the current to max 1mA for max. VCC. Other passives are just for filtering.

The measurement frequency shall be not faster than 1Hz.

Can you see any issue with this setup that might invalidate our thinking?

Thanks