I've had a Fluke 8050A bench multimeter sitting on a shelf in my cold, damp garage for about 30 years. It was new in 1981, last powered up in the 1980s, and the display was dead. I came across these fine instructions for display repair and thought I'd try. I was encouraged to find that the original Fluke manual included the schematic, the layout and the calibration process.

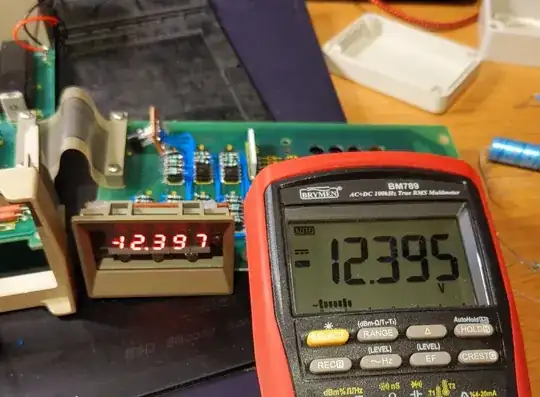

I replaced the 40-year-old NiCads and wired up one digit of the display. By this time, the DMM had had about two minutes powered on in the last 30 years. My one digit seemed sensible so I wired up the rest and turned it on. It worked! All the buttons worked and the display looked credible in all modes, so I gave it some DC input and compared it with a 6-month-old DVM.

Great! Not bad drift for 40 years since last calibration!

Unfortunately, everything went downhill from there. The Fluke DMM has a Mostek MK3870/20 single chip processor which drives the display. That has 2kBytes of mask programmed ROM and 64 bytes of RAM. It's in a 40 pin plastic DIP package.

After a total of maybe 5 minutes of power-on time in 30 years, the processor started to misbehave. First it displayed voltage correctly, but confused the decimal point. Then it would display the correct voltage for a fraction of a second before then displaying all zeroes. Then it displayed random output as the Fluke buttons were pressed. Then it failed to write the display at all. And finally, its 4Mhz built-in oscillator stopped oscillating. It was dead. All this happened over perhaps another 10 minutes. Measuring everything, I'm pretty confident that it's the processor chip itself that failed.

A tragic tale, but at least the old DMM got to measure one last voltage before it died.

Is this sort of failure in a 40-year-old plastic chip to be expected? What might the actual failure mode be? Water ingress? Is there any way I might have avoided it?

Those who wish to close this question as opinion-based, please note that I am not asking why my DMM is broken. I am asking what failure modes exist for a 40-year old plastic chip, long unused, and what mitigation might help.

Thanks!