We'd like to use plain automotive connectors to connect our thermocouples.

What we are looking for is the ruggedness and economy of such connectors.

Of course, that brings the problem of material change and cold junction compensation.

Since we already have a gradient between the thermocouple amplifier (ex : INA826) and the real cold junction (entry connector,) I figured we could shift the cold junction all the way to a remote connector and use copper wires from then on. The cold junction temperature would then be sensed by another temperature sensor and the compensation would be made in software between the perceived emf at the In-Amp input and the converted Cj T° to voltage.

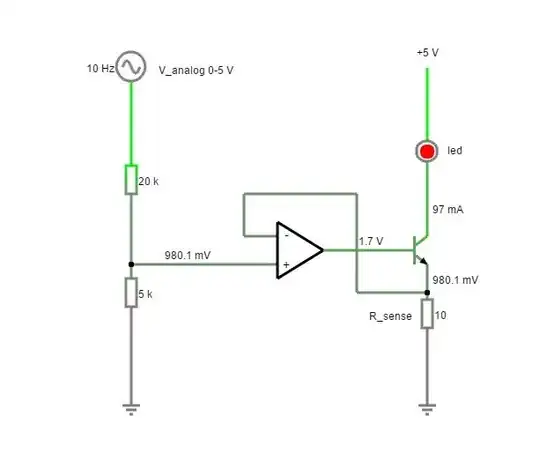

Below is a principle schematic for your review:

Does all of this make sense or do you see a flaw in this way of operating?

How about the plating of the pins (tin, gold, or nickel) would that bring yet another error?