Spring cleaning, and I'm trying to get power supplies for all my devices with missing power supplies. They're all the typical barrel power connector, and I'm having a dickens of a time trying to figure out the pin/hole diameter.

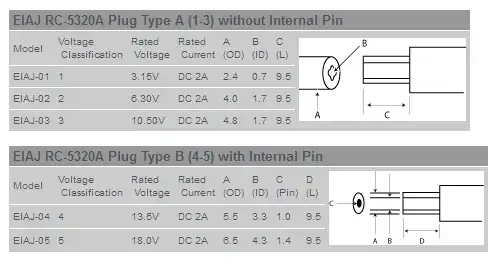

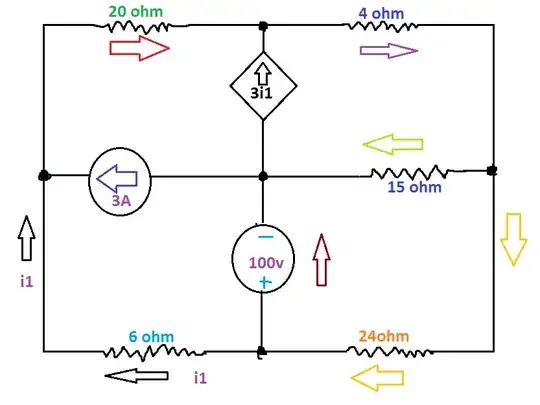

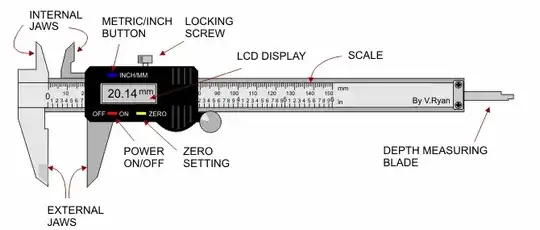

I ordered the power supplies I needed based on outside diameter (e.g., 5.5mm in my example below) and was surprised to discover that while the jack fit, the center pin did NOT. How do I prevent this from happening in the future? Do they even make calipers that can get into the hole to measure the pin diameter?

Radio Shack has their little keyring behind the counter with every known tip size, but all they can get from that is which stock number fits on their universal wall wart. Personally, I think that these types of "universal" kits are the worst thing to happen to electronics in, like, FOREVER. Too many parts to misplace and the tip-to-cable connector is almost always proprietary.

If I try to pump them for information about what the outer and inner diameters are, they want to know if I'm happy with my current cellular provider. As you may surmise, I'm not a big fan of trusting my local Radio Shack for electronics guidance.

So...that leaves me with a bunch of power supplies that don't fit their devices, and me a little peeved that I have to deal with RMAs, return shipping, etc., especially when I really don't have a clue how to figure out what to order. That also begs the question about how to ensure that I buy the right jack when designing something that NEEDS wall wart power.

Where do I even start? Anyone have any ideas on how to finding the correct barrel & pin diameters when I don't have specs on the jack? Is it really trial and error? or is there some measurement device that's available to help?

(Photo courtesy technologystudent.com.)

(Photo courtesy technologystudent.com.)