So after a very long effort, I think I've finally come towards the end of my PCB board design. It's a two layer board with no ground or VCC plains (Re-routing is not an option) as I can't go though the grief process again.

My question is should I use a copper pour? Currently I have three possibilities which I am contemplating.

- Do not use a copper pour

- Implement a copper pour connected to nothing (no signal)

- Implement a copper pour connected to ground

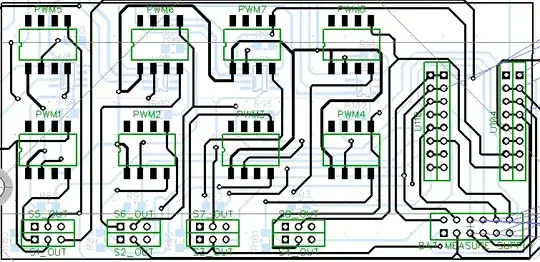

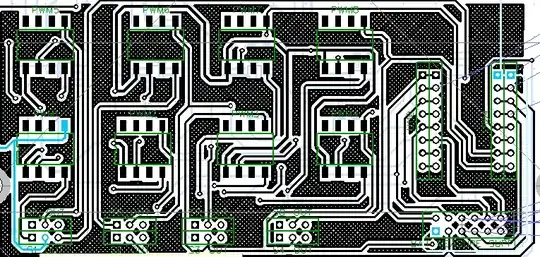

A brief example is below.

Unpoured PCB

Poured PCB with cross pattern

What are your thoughts and why?