I have recently noticed some toroids wound with what I consider to be huge space left over, and I am asking if there is any good reason to do this. (or even an acceptable reason would do). My thoughts are that if toroids can "whine", that you want to wrap the wires relatively tight to the core so that they don't move, not set them up perfectly for a host of resonant vibrations. I am also thinking that the DCR is needlessly increased, and therefore efficiency reduced.

Possible reasons for me might be better conductivity of the copper through less deformation / work hardening and therefore removal of the need/desire to anneal. Is leakage inductance affected?

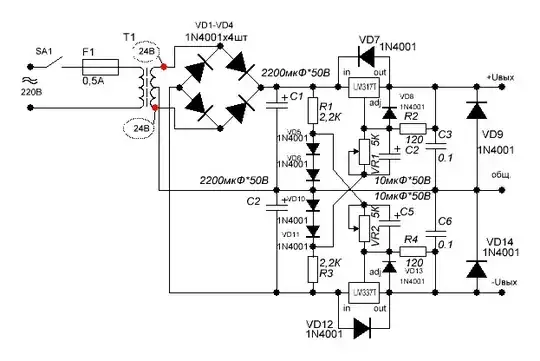

In this pic, all have needlessly large gaps between the wires and the core except last one, which is conventionally tight-to-the-core (though thicker). You should be able to see that for the first toroid, there is space both inside and outside.

EDIT:

Here is a close up of what I mean, just to be clear:

And here's another one. Doesn't this look much to easy to deform?