I'm developing a circuit to power a 300W DC motor with 25A rated current. I have experience powering smaller motors with motor driver ICs, but I can't seem to find an in-stock motor driver IC designed for a more powerful motor like this.

The motor is powering a parking brake mechanism. My requirements are basic: drive the motor in either direction to enable or disable the parking brake through a gearbox and some mechanical elements. There is no need to control speed. Stop the motor when the current exceeds a threshold indicating stall.

I don't think I really need a motor driver at all. I'm thinking I should just drive a MOSFET h-bridge from the microcontroller with something to increase gate voltage with a current-sensing resistor to detect stall via the microcontroller's ADC.

Are there any pitfalls or concerns I should watch out for driving a motor without a motor driver?

Update

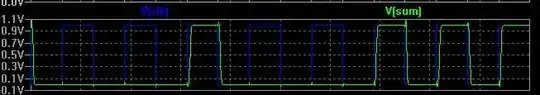

Here's the circuit I'm currently thinking. Planning to separately drive coils as suggested to prevent shootthrough. I didn't see a DPDT relay with more than 10A contact current rating so I used two SPDT relays. Doesn't even look like I need an amplifier for the current sense since I'm only trying to detect stall