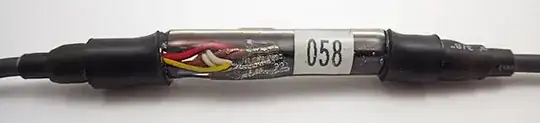

I'd vote for glue-lined heat-shrink.

Alternative, if you can live with making holes in the tank or not fully submerging the sensor, would be to use automotive engine coolant temperature sensors - these, by definition, are sealed when screwed into a hole in the engine block with coolant flowing past. The external connector is not always guaranteed submersible (but many are, modern GM stuff uses AMP/Tyco weatherseal connectors for example) but they can be sealed easily enough, and the sensors are very robust, designed for high temperature, chemicals/oils, vibration, etc.