Please refer to post PWM generator circuit review for initial simulation and bugs on the circuit.

In general, the circuit works very well and I can control a 12V fan with the PWM output of the 555 which is varied according to the potentiometer. However, I am experiencing the following issue:

After around 1-2 months of constant use, it is like the gremlins come overnight and change the timing circuit... The selected frequency of 25 kHz for when the duty cycle is 50% shifts to a higher frequency...

The passive components aren't getting degraded. I know this because as soon as I replace the 555 with a new one, the frequency goes back to 25 kHz.

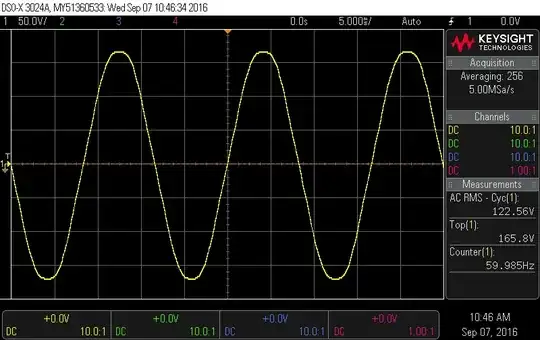

Here is a photo of the broken circuit output after 1-2 months of constant use:

As you can see, the frequency at 50% duty cycle is 32 kHz

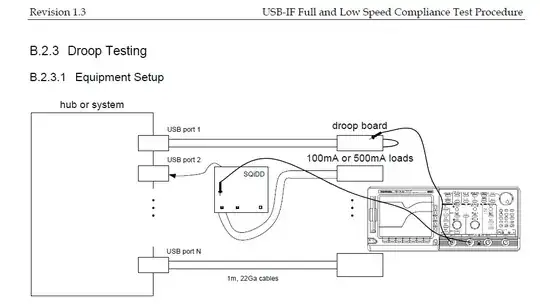

This is now the SAME PCB but with the 555 swapped for a new one:

Now, the frequency is back to the required 25 kHz.

I chose a NE555D from Texas Instruments instead of a cheap Chinese one precisely to avoid stuff like this happening but it did not do the trick apparently.

The circuit is connected to a 12V/1A "wall-wart" power supply and a 12V fan. There are no extreme low/high temperatures and no ESD events as far as I am aware as the pot has a plastic dial inserted.

Does anybody know what could be happening that damages the 555 after a prolonged used time?

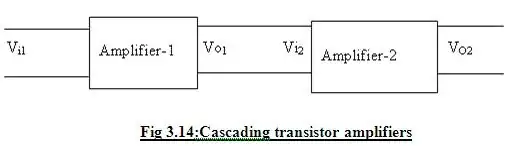

Here is the full circuit for reference (R5 is DNP), previous oscilloscope shots are from probing pin 1 in J2.

Thank you

Update 07/10/2021

I tried soldering back again the "broken" 555 using solvent and a toothbrush to clean the PCB. Initially, it looked like it worked, and I even reswapped to make sure this is correct. Then, everything started to lose coherence. I saw with my own eyes on the oscilloscope how both the duty cycle and frequency started to slowly drift but this time to lower frequency instead of higher to the point that the fan turned off. I think using the heat gun a few times on the IC made me damage the parts... I am now testing a board with a 10K pot and 3.3nF cap to see how it behaves.

The big issue here is that I don't exactly know what is happening and this problem only manifested after 2 months of use. Because I thought the circuit was good, I already manufactured 2700 of these PCBs for my product.

The challenge now is to take the right course of action:

- Do nothing and hope it was just environmental and assembly conditions such as dust and excess flux

- Change the RC network to a lower resistance value and higher cap. This will involve buying new components and paying the factory for the rework

- Same as 2 but change the 555 for a TLC555 as these are more precise and deal better with smaller capacitances. Components are more expensive than option 2 but rework should be cheaper

- Use an MCU instead such as the ATtiny202... Most expensive option as I will need to get a new PCB and buy components, also the price per unit will be higher to not mention supply issues with the part...

#hwentreperneur