I have a couple of meters with analog scales and want to know why they have a shiny metallic area following the scale.

-

7Damn young punks get offa my analog electronic lawn :-) . Next someone will ask why old oscilloscopes had circular displays! – Carl Witthoft Sep 30 '21 at 13:01

-

1It's often known as a mirror scale, or mirrored scale. – Andrew Morton Sep 30 '21 at 15:41

3 Answers

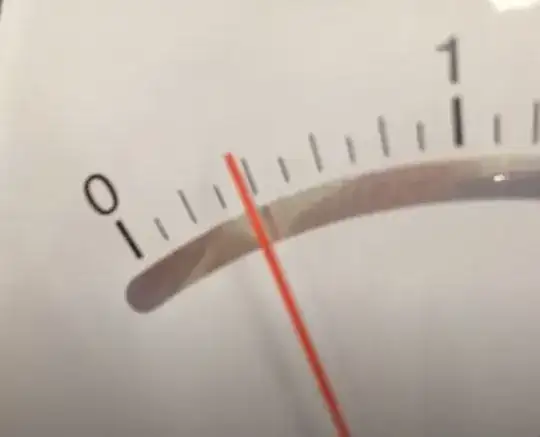

The mirrored bands are to solve the problem of parallax when reading the meter. The technique for reading the meter is to adjust your head position relative to the meter so that the reflection of the pointer is obscured by the pointer. Then you are confident that you are looking at right angle to the scale and can read the value without parallax error.

Figure 1. Needle reflection is visible and reading appears to be < 0.4.

Figure 2. Needle reflection is obscured by the needle itself and reading now appears to be much closer to 0.4.

Images from YouTube.

- 168,990

- 12

- 186

- 385

-

-

-

@DKNguyen the needle, or at least its tip, is usually pretty close to the dial (at least on my callipers and indicator. If large analog movements were made that way, play in the bearings would result in troublesome contact with the dial much more often. – Sep 30 '21 at 21:16

-

@user_1818839 So you're implying it might just be the size of the dial? I guess the circular area of an indicator and caliper dial is only 1/20th that of an analog volt meter (if it were also a full circle). – DKNguyen Sep 30 '21 at 21:21

-

@DKNguyen That has a lot to do with it, I have never seen a dial caliper with a 100mm dia scale. But calipers and TDIs can also have low clearance bearings, with slightly higher friction, in order to constrain the needle tip location. If you did that with a sensitive MC meter the friction affect accuracy. So they have play, like a watch balance wheel's four jewel bearing, which means the needle must be kept clear of the dial. – Sep 30 '21 at 21:23

-

@user_1818839 I didn't realize they built in friction to mechanical indicators. – DKNguyen Sep 30 '21 at 21:34

-

It's not built in, just a consequence of closer tolerances rather than what I've seen called a "rattling horological fit"! I'm not 100% confident of this hypothesis; for example I've never seen an aneroid barometer with a parallax mirror, and you certainly don't aim for friction there. – Sep 30 '21 at 22:40

Anti-parallax.

When the reflection of the needle disappears behind the needle itself, the reading is accurate. Otherwise, you may be looking at an angle, and reading the wrong figure off the scale.

(Presumably on the SWR power meter, the reflected power is either less critical, or known with less certainty, so it doesn't need parallax control. Typically you'll tune something for minimum reflected power, and you can see the needle reach a minimum from any angle)

-

In the SWR meter, it is either the forward power important, or the SWR - and SWR grid is not that much accurate anyway, – fraxinus Sep 30 '21 at 07:06

It is helping to adjust the looking angle, a.k.a. solve the parallax problem. It is exclusive to analog displays. It's old, reliable technology rarely seen these days; get off my analog lawn young punks.

- 11

- 1