My soldering iron was working fine for a few years. One day, I used it and it worked fine again, then I unplugged it then tried to use it again a couple of hours later but it wouldn't heat up.

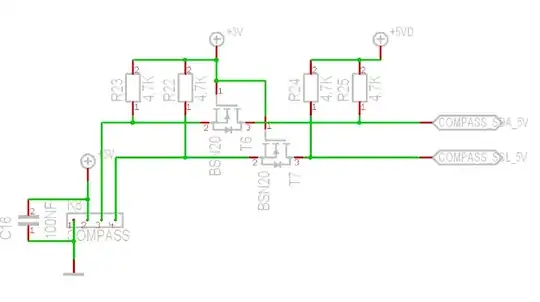

I took it apart and pulled a Big Clive and mapped out the schematics. I tested the few components and they seem fine. Both of the SMD resistors check out as does the SMD capacitor. The diode doesn't register with the diode-tester on my DMM, but my Mega328 ESR/LCR tester detected it as a diode. I don't know what resistance the pot should have, but it definitely seems to have a range (it's not shorted or open).

The 97A6 thyristor/triac seemed dead (I don't recall the exact nature of the failure), so I got a pack of MAC97A8s, tested one, and put it in. I don't think the orientation of the triac should matter, the gate is in the center either way and iirc, the anodes are both functionally equivalent.

The only thing left that could have a problem is the ceramic heating element, but I have no idea how to test that (I don't know what properties, such as resistance, it's supposed to have).

Is there some way to diagnose the problem?

I already got a replacement, but I'd like to salvage this iron and avoid throwing it out if possible. (My old one with the wire-wound element died the same day this one died, so I'd like to keep this as a backup until I can get another backup backup, and also just not waste what seems like a perfectly usable iron—well, other than the not working. )

Front (with new triac):

Back (with wires splayed to show traces—yes, I know I didn't trim the leads yet):

Back (with wires splayed to show traces—yes, I know I didn't trim the leads yet):

Original triac:

Original triac: