Why is the set of white labels on a PCB called the "silkscreen"?

Why is the set of white labels on a PCB called the "silkscreen"?

It's called silkscreen because this is the name of a type of printing: screen printing.

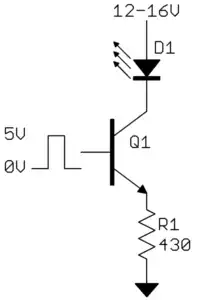

The traditional screen printing process is like this: Inside the frame is a sheet of fine woven material (the silk) which is porous enough that you can push paint through it using a squeegee. A mask is placed between the silk screen and the paper. It's all pressed together, then the squeegee is wiped across the screen. Paint is pushed through the mask onto the paper, forming the image. Really, the only job of the screen is to protect the mask from the squeegee.

A similar process is used when printing the white paint on PCBs. However, instead of a separate mask, the screen is covered with a photosensitive layer, which is developed to produce the required mask as part of the screen.

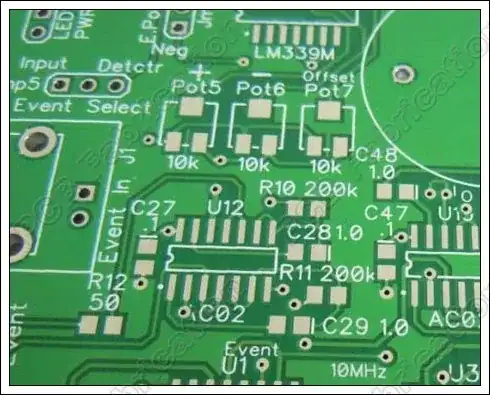

Of course, for PCB manufacture, this process is done by machine:

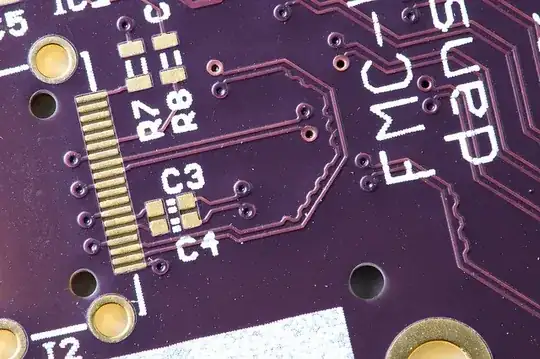

If you look closely at a PCB, you can see that the silk screen image is actually quite rough, and it's apparent that the image was pushed through a net.