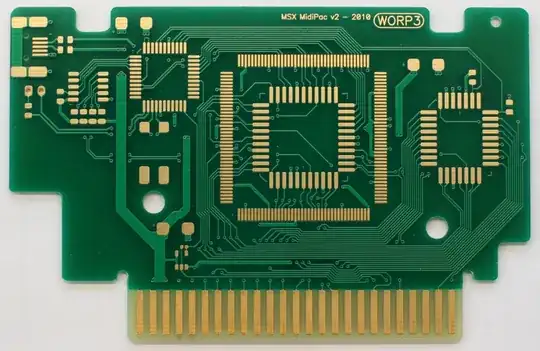

I have in front of me a raw PCB. The surface mostly has three colors: dark green, orange-gold and white.

As I understand, the green is resist, the orange-gold is copper, and the white just the silk screen.

I find it surprising the color of the PCB's surface copper is quite different to the color of copper pipes. Please compare the orange-gold of PCBs, and the reddish-orange of copper pipes.

Why does PCB copper look more yellow than copper pipes?