Does anyone have a formula for calculating the inductance for a coil wrapped around a rectangular non-air core? Seems trivial but this is the closest I've come in searching, and this is for air-core only: http://electronbunker.ca/eb/InductanceCalcRc.html

What I am trying to determine is the amount of inductance I will have with a 25.4mm x 6.36mm core currently made up of micrometal mix 40 (60 ur) (https://www.micrometals.com/products/materials/-40/) and N turns of wire. While I may be able to simply multiply the value from the above site by 60 for the low freq's I am using (< 5Khz if it were to be driven continuously), without knowing the formula used I'm not certain of that.

I do not yet know the number of turns of the coil (I will use as many is required), or the pulsed amperage (as that depends on the total inductance and resistance, which I am trying to minimize to reduce the total current required). My best WAG for current is around 100 Amps at 6v for < 0.1ms. Minimizing the width of the coils is important to keep the magnetic flux lines as short as possible to the keeper.

Physically the core is arranged in a pattern as shown bellow, similar to a U for a transformer. A permanent magnet is inserted between the vertical cores (6.36mm width as shown, 25.4mm depth). One "coil pair" is on each side of the U. These coils will be quickly pulsed (maybe 3T) once to create a large magnetic force to change the flux path of the permanent magnet from going across the keeper to going across the gap at the bottom (with a piece of steel in place as shown on the bottom). The coil polarity can then be reversed and quickly pulsed to drive the flux path though the keeper to release the steel.

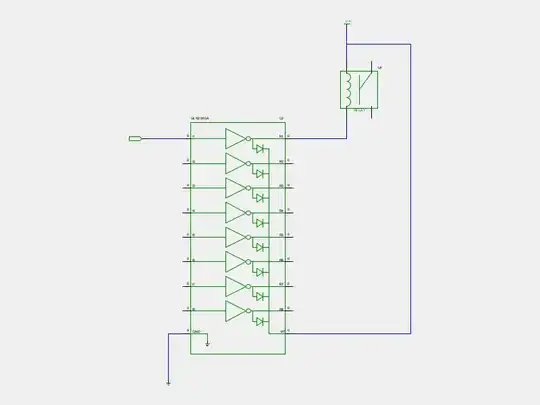

I plan to drive the coils with a MOSFET H-bridge.

Thanks in advance...