I got this project a month ago and I've been working on it but I just can't seem to figure this out and my professor won't help us. The project is to build a device to correct the patient's walk -in a crude way. Instead of actually "fixing it" I need to turn on 1 or 2 LEDs to show which out of 8 sensors are most pressured. I can only use comparators and op-amps to turn on the LEDs. It's given that only 1 LED can be turned on(the sensor with most force) or if 2 sensors are close in voltages (+/- 10% V) then both of those sensors LEDs would turn on.

Basically I would have 8 sensors on the foot that would measure the pressure and convert it to voltage (linear) which I would use to determine which one is the most pressured one. Now this doesn't have to be a real example so I don't need to worry about which specific component I'm going to use, I need more of a general idea.

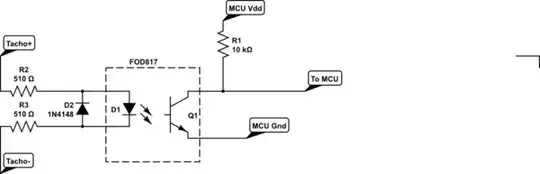

So far I've been able to convert force to voltage using two PNP transistor and getting a constant current source on each of the sensors and I've created a circuit to ,"find" the highest voltage from all eight sensors and only output it, using op-amp and some diodes.

Only problem I have is how to figure out which LED to turn on using comparators and a bit of op-amps and how to add that +/- 10% comparison between all the voltages. When I asked my professor only thing he said, "It is not an interesting situation when the voltages are equal, but when they are sufficiently different, which can be interpreted as improper reliance."

Project : "Based on pressure differences turn on one LED of eight, which shows the approximate position of the foot, that is, which is the most loaded sensor. If the load on the two sensors is equal (in limits +/- 10%), two LEDs should be switched on. Make a signal to turn on the LEDs using differential amplifiers and comparators that compare the difference of two voltages with zero, and if the difference is less than zero, turns on one, and if it is greater than zero, turns on the other LED."

Constant current source

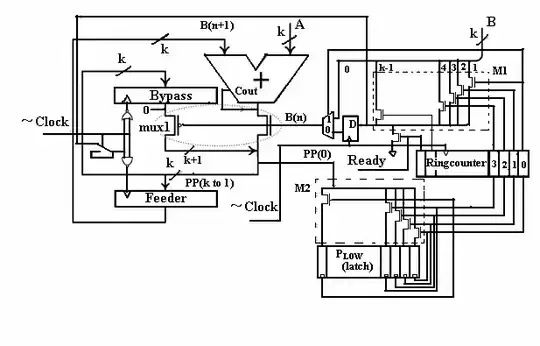

Finding the highest voltage

Finding the highest voltage

Some idea I had about the LED logic using diff op-amp and a comparator

Some idea I had about the LED logic using diff op-amp and a comparator