I have an ATmega32u4 which I have configured to run its application by default at boot, and to run the bootloader (standard DFU USB bootloader from Microchip) when the reset button is pressed. I intend to use the bootloader for flashing the application using Atmel Flip.

I have the fuse bits set as follows:

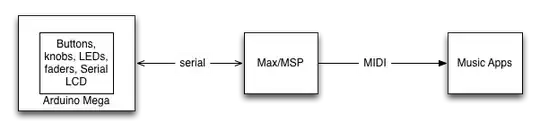

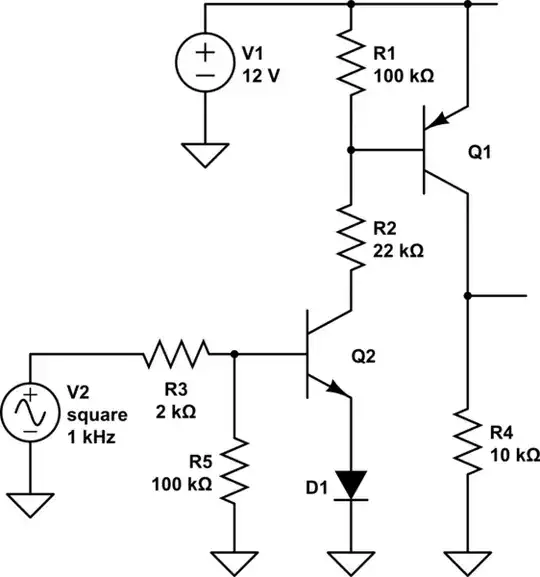

And my reset circuit looks like this:

But, I found that this did not work - and the bootloader is always run at power-on instead of the application. This is a little baffling, but it gets worse...

I found that if I remove the 10 k pull-up (R441), it works as expected (the app runs at boot, and bootloader runs on manual reset).

Furthermore, I found that if I leave the 10 k installed but replace the 1 µF cap with 0.1 µF it also works.

And if I remove the cap altogether it works as well.

- Fails

- R441 - 10 k

- C166 - 1 µF

- Works

- R441 - DNI

- C166 - 1 µF

- Works

- R441 - 10 k

- C166 - DNI

- Works

- R441 - 10 k

- C166 - 0.1 µF

At first I thought the time constant with the 1 µF cap was too large, and the µController was reading the pin as a reset (active low) at boot, but that doesn't explain why it works when R441 is not populated. The ATmega32u4 has an internal weak pull-up, and using it alone would cause a much larger charge time.

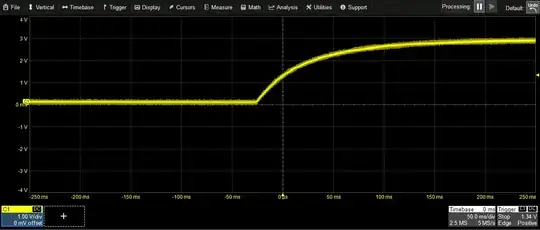

I can't find the value of the weak internal pull-up in the documentation, but I estimate it to be somewhere around 50 k, based on some oscope measurements:

Probe at TP87

With R441 un-populated (and 1 µF cap):

With R441 (10 k) installed (and 1 µF cap):

I plan to go with the 4th configuration in my bullet points above (10 k and 0.1 µF), but I would love to understand why it is behaving this way. I would hate to find that it is working now, but fails to work later when fielded due to a new thermal environment or something.

Notes:

- The HWB pin is pulled to ground through a 10 k

- The HWBE and BOOTRST fuses are configured such that the application code should execute at boot unless external conditions apply: namely that reset is pulled low, sampled on the reset’s rising edge.

- The application itself has no calls to jump to the bootloader.