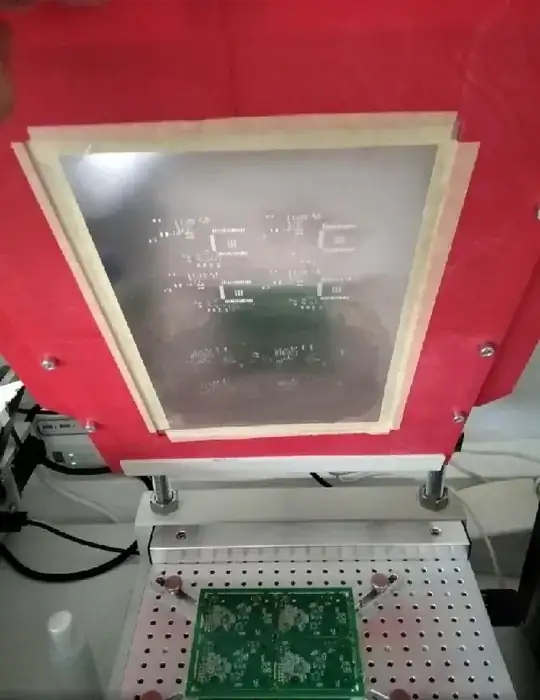

I am trying to do a home assembly of PCB but I have issues after reflow soldering. Especially I have bridges/shorts on the pins of QFN packages. I have assembled multiple boards other joins are okay but each time I have randomly bridged pins on QFN.

Probably the issue is the stencil printing. Can you give me ideas to improve my process?

I am using SN42BI58 paste, mixing it before apply, and using proper, suggested by manufacturer, temperature curve. So I think the soldering process is OK.

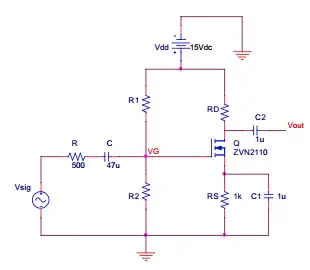

I am using a manual ZB3040H stencil printer. I have an 28x40cm big stencil and an unique 3D printed stencil frame.

I think the stencil is not to rigid/stiff and that produces more paste on board as should.

What can I do to improve my technology? How can I use 28x40cm sheet stencil with my ZB3040H frame based stencil printer?

Here are some pics: