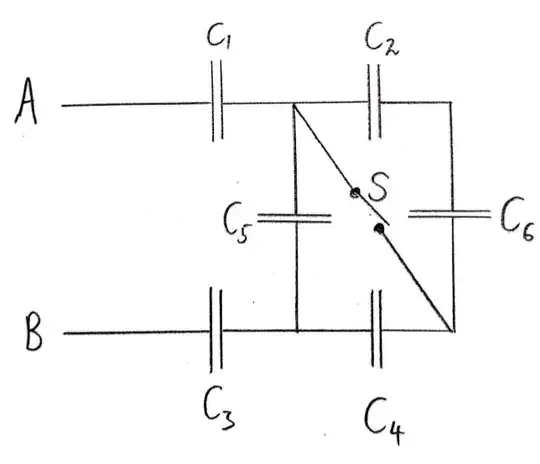

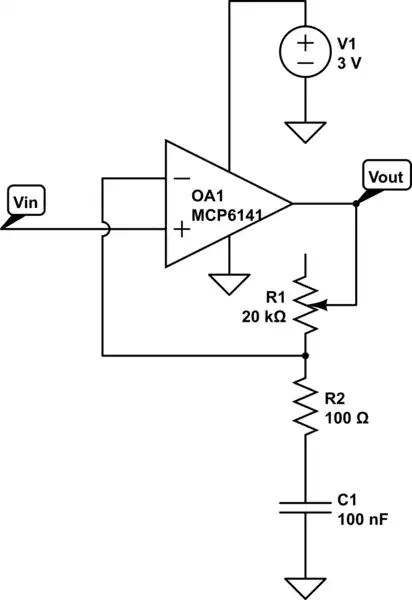

I'm working on a phase angle controlled TRIAC dimming circuit (schematic attached below), and I'm seeing a lot of ripple/noise on the 120 VAC input as I near 50% power. I'm wondering what I can do in my circuit to possibly clean the line to reduce or remove the ripple, and I'm open to any other improvements that might be suggested. Powering the induction motor is introducing line noise and appears to be impacting the zero cross detection circuit's signal where I'm starting to see phantom ZC pulses in the arduino, presumably from sub-harmonics on the now noisy signal.

I'm building this project to learn more about electronics which is why I've opted to design the circuit instead of purchasing things like zero cross modules and off-the-shelf SCR units. As such I'm wondering what other's would do to the current schematic to improve it's robustness/durability/etc.

The circuit is powering an Ametek 116765 vacuum motor, rated up to 13A peak current draw. I haven't taken the motor above 35% power yet, but so far it runs smoothly from 0 to 35% power.

The TRIAC is a snubberless design, and I don't seem to have any problems with latching the TRIAC so I've not included a snubber.

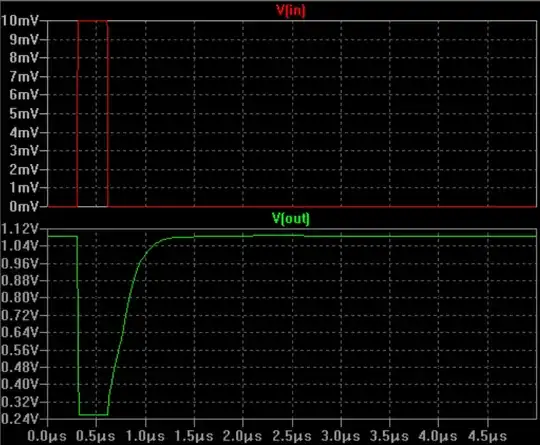

Here's a capture of the TRIAC (green) running at 35%. You can see the amount of ripple on the AC line. It also overshoots the zero cross, but I've read that it shuts off at zero current not zero voltage which is why you'd see that. I believe that's fine, but if there's an improvement to be made I'm open to suggestions.

Here's the impact on the AC (yellow) as it enters the circuit. You can see a voltage dip as the motor kicks on. (Note: that blip at the peak just before the voltage dip appears to always be there, even under no load...)

Here's a closer look at the impact on the zero cross pulse. Under no load it's a nice bell curve.

Update #1:

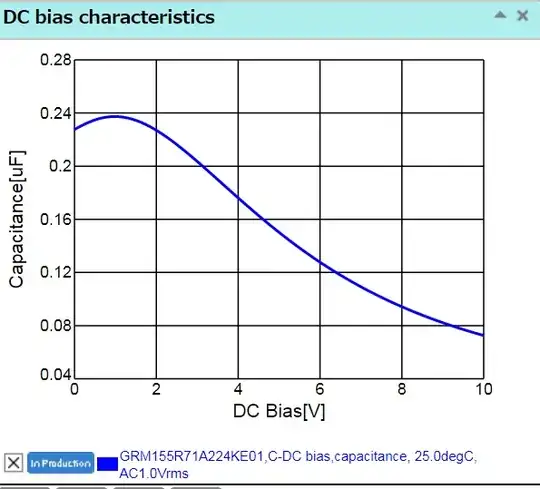

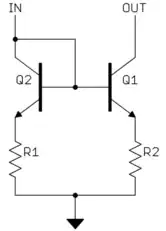

I've added a snubber to the circuit based on the suggestions of the several folks who responded, and to my eyes it has no apparent impact on the voltage spike we're seeing. Below are 4 different snubber setups and their corresponding captures. Also, I'm following the layout discussed in the opto's datasheet described in figure 12 show here:

No snubber:

1k resistor + .1uf cap:

3k resistor + .1uf cap:

3k resistor + .5uf cap:

From what I'm seeing, there's a few potential outcomes:

- The snubber is not needed since I'm already using a snubberless TRIAC

- The snubber is sized incorrectly somehow, and I could use recommendations for sizing

- The snubber layout is incorrect somehow, and I could use recommendations for appropriate topologies

I'm open to any suggestions you might have.