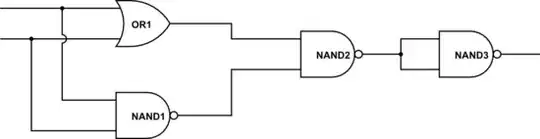

I am planning on building a PWM fan controller using a 555 chip. I have found the following schematics for it:

The fan I will be using is a Noctua NF-A14 Industrial 3000. From the data sheet, I see that draws at most 0,55A.

I am planning on using a 12V 1A power adapter for this project. What are your suggestions for lowering the voltage from 12V to 5V? Should I use an LM317 or 7805 or do you have better alternatives?

Also for the 555 PWM controller can you suggest other schematics different from the one I’ve posted?