This is really an answer relating to all three of your recent questions.

The focus on skin depth, whilst a useful benchmark, is not the whole story for electrically small shielding. For fields at 36kHz, the wavelength is 8.3km, so your enclosure is electrically small. Also, unless the source of your interference is greater than several km away, it is likely that the fields may be predominately electric or magnetic, rather than have the normal wave impedance of free space.

Let's concentrate on electric fields for a moment. If I have a static electric field and I have a small aluminium shell (think ping-pong ball or matchbox), then the charges on the surface will arrange themselves so that the E-field inside is very small. Now imagine the fields changing at a 1Hz rate, the charges on the surface will rearrange themselves every second, currents will flow and the fields inside will likely increase slightly, and the slower the rate of change, the less they would increase. If you assume that you can estimate the internal fields using the skin depth, you find that you are predicting that the internal fields increase as you slow down the rate of change (as the skin depth increases as the frequency decreases) - this doesn't make sense. Clearly something breaks down in this approximation.

On the other hand, if there is a steady magnetic field present, you would expect it to penetrate the shell without loss, and as I slowly change it it still penetrates.

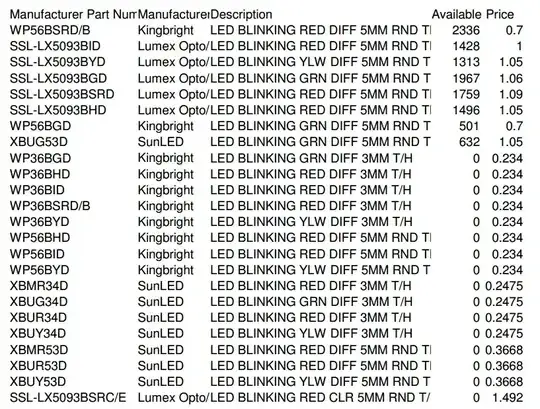

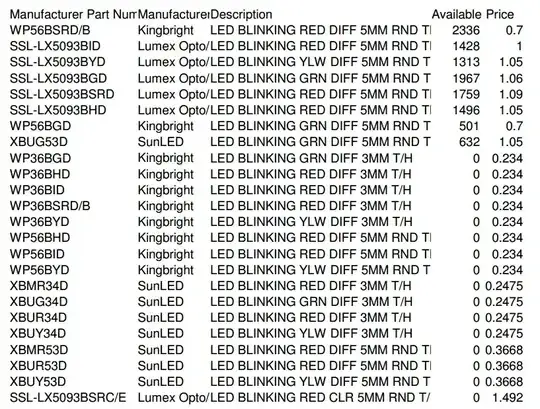

So how to get a handle on what is happening? Well there are some canonical problems that can be solved analytically that give insight. You can find the solution of a lossy conductive spherical shell here. Tesche calculates the shielding effectiveness of a 6 foot (1.83m) diameter aluminium shell 1/32 inch (0.79mm) thick under plane wave excitation. At 36kHz, the electric field is reduced by over 200dB, and the magnetic field by close to 70dB. Not bad for less than 2 skin depths!

Taking his figure 2(b), H-Field transfer function, I have added points calculated simply using the skin depth showing how far off they are:

So now let's apply this to your problem. It clearly suggests that there is a chance of shielding with a cheap aluminium shield. You have tried aluminium foil and failed. One possible issue is that you didn't pay enough attention to joining the foil, you just overlapped it relying on the capacitance. Whilst this is great for UHF and above, you can't rely on it at these frequencies. Even if you got 1nF of capacitance at each overlap (a lot), at 36kHz this represents over 4k of impedance - imagine laying a lot of aluminium squares and connecting them by 4k resistors - this would be a very poor approximation to a continuous aluminium shell.

So there is hope that your aluminium shell may work if it is properly constructed. It should reduce the electric fields inside. If your problem is magnetic fields and your DUT is sensitive to magnetic fields, then all bets are off.