I'm actually a mechanical engineer, so I'm not very versed in electronic design, here goes:

I want to design an inductively-coupled network connector for the rail industry. The goal is to have a data link along the whole train.

Some key points to consider:

- There is currently no electrical network across the train. Automatically coupling contacts connected to the mechanical coupler have been tried but are extremely difficult to make reliable. What does work is having axle generators and buffer batteries on each wagon.

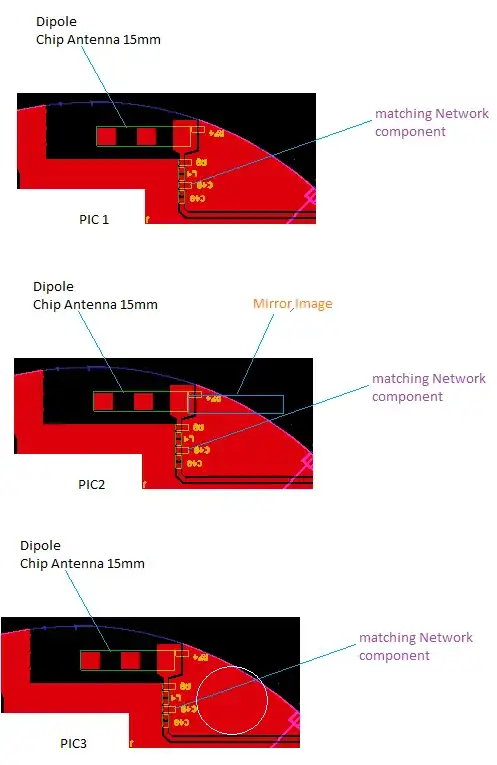

- I want to be able to "bypass" a "dead" wagon (wagon with nonfunctional electronics) inside a tunnel. This pretty much rules out wireless systems, as I believe they will have great difficulty to reliably send RF signals around the dead wagon. I was thinking of using the following network topology to solve this:

- I'm going for a physical connection here because when you connect a string of wagons, they all automatically register to the locomotive. Trains get built in yards with a lot of wagons, so you want to be sure that you're not incuding wagons on the adjacent track in your wagon list through WiFi.

- I really need only very minimal data rates. Mainly you will have the loco telling the wagons every 100 ms to not brake (fail safe) or *brake at X% and the wagons reporting back that they are all still there (train integrity.) The other data is not time critical. Video is nice to have (to be able to back up the train with a rear-viewing camera without leaving the cab,) but a non-reliable link via normal public LTE would be fine.

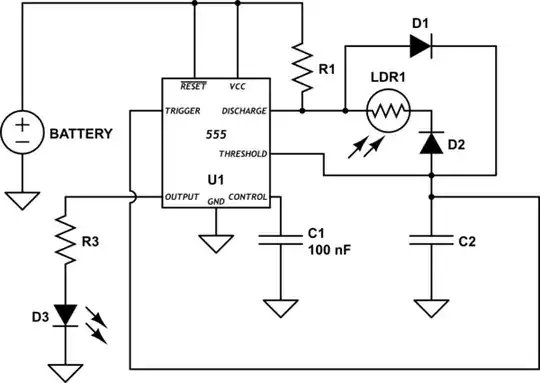

I had a look at the electrical setup of Ethernet. I saw that there are always pulse transformers for galvanic isolation (and a commom mode choke between the cable and the board.)

I had the idea: Why not make a physically separable pulse transformer to transmit magnetically? I wanted to build a demonstrator network which looks something like this:

Here are my questions:

If I buy an Ethernet pulse transformer, saw open the ferrite beads & re-arrange and re-wind them to make them physically separable, is this likely to actually work (provided the bead halves are well-aligned without an air gap?) Any recommendations on what to buy and tinker with?

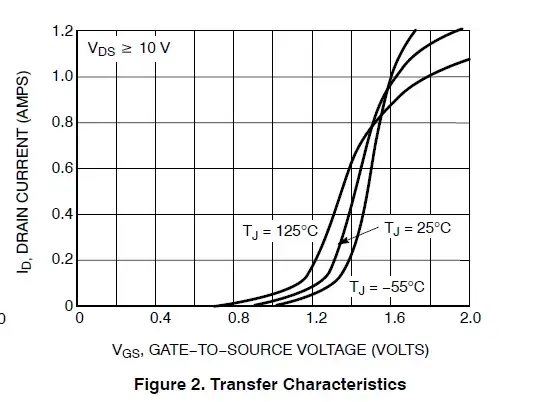

In the comments you told me that Ferrite is very brittle. Also the beads are very small. What sort of losses and what sort of frequencies would be possible with a ~10mm mu-metal sheet core? I understand that this would no longer be within Ethernet standards. Any recommendation to use an Ethernet-style slower network?

I'm very happy for any help I can get, thank you!

Here is visualization of the idea on the coupler head with 3 pot-cores set in resin inside a sturdy milled case:

*Here is some background to my task: I'm in an industry comittee looking into freight rail automation. We want to design a highly reliable communication network for freight railroad cars.

The main problem is that the rail industry is very conservative, so everyone goes with the purportedly "tried & tested" design. In the passenger transit area, electric couplers have been in use for around 100 years with hundreds of individual electric pins (the rail industry still a fan of hard-wired functions) which wear, have to be kept clean and are protected by flaps/doors and are often heated to avoid problems with moisture. (You can see the doors open and the bare pins on each side of the coupler at minute 1:10 in this video.)

There is just no way that this is going to work reliably in a freight environment. Even if we assume passenger-level care for the couplers, in the passenger world you couple 2-3 units maximum, not 30-100.

That is why I wanted to design a system which is powered by axle generators and buffer batteries, but transmits via a physical ink on the coupler via an inductive connector. I would like to avoid simply going fully wireless because of 2 reasons:*

- I want a physical connection so when you connect a string of wagons, they all automatically register to the locomotive. Trains get built in yards with a lot of wagons, so you want to be sure that you're not incuding wagons on the adjacent track in your wagon list.

- Everyone is terrified of hackers, I think it would be easier to prove functional safety & information security (against information tampering, not eavesdropping) on a physical connection.