If you don't want to do calibration in software (which has its own potential issues), use the trimpots but limit their range by adding other resistors so that they don't have excessive adjustability.

For example, if you have 10K + 10K in that position you could do something like this:

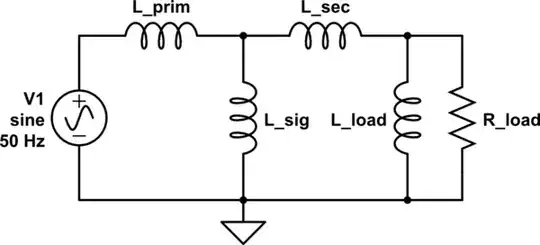

simulate this circuit – Schematic created using CircuitLab

This is just a rough example, you should do a worst-case error budget including all reasonable factors and give yourself a bit of headroom so the pot is never right at either end. This will also prevent the technician doing adjustments from "calibrating out" a serious error such as the wrong part being populated elsewhere, which can cause subtle issues.

In this case you can easily set the ratio to a few ppm and it should stay within 50ppm or so. If you don't limit the range, the stability may not even be as good as ordinary 1% resistors, and perhaps much worse if you're not using it as a voltage divider.

The "paint" you have seen is typically used to indicate that the unit has been calibrated and to combat "screwdriver drift", so warranty can be voided or at least the issue detected. Since those trimpots are sealed, pretty much any kind of paint can be used, such as nail polish or lacquer.