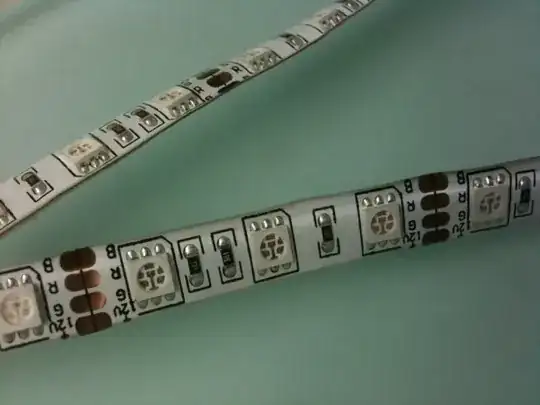

Does anyone have a good solution for a mechanical connector for flexible printed PCB, like those used for strips of common-cathode RGB LEDs?

(You can cut the strip across any of the solder pads and scrape back the silicon insulation)

"Just solder" isn't the answer I want to hear (neither is "get better at soldering") as a) I need to do lots of these joins which need to be b) mechanically sound and ideally c) field-repairable, in quite a tough field (on the playa at Burning Man.) The joints need to be mechanically sound as I plan to sew about 30 x 50cm strips into a garment.

Ideally I'd like some kind of screw-terminal. But I don't know what to ask for and can't find one on my own.

Another idea I've come up with is taking 90° header pins and pushing/piercing/drilling little holes for them through the printed track and soldering those in (a much easier task—I've found component-through-hole soldering orders of magnitude easier than wire-to-pad soldering; tracks lift and it's hard to get everything to bloody stay still.) Anyone think this might work and/or tried it?