I want to make an LED panel as shown below:

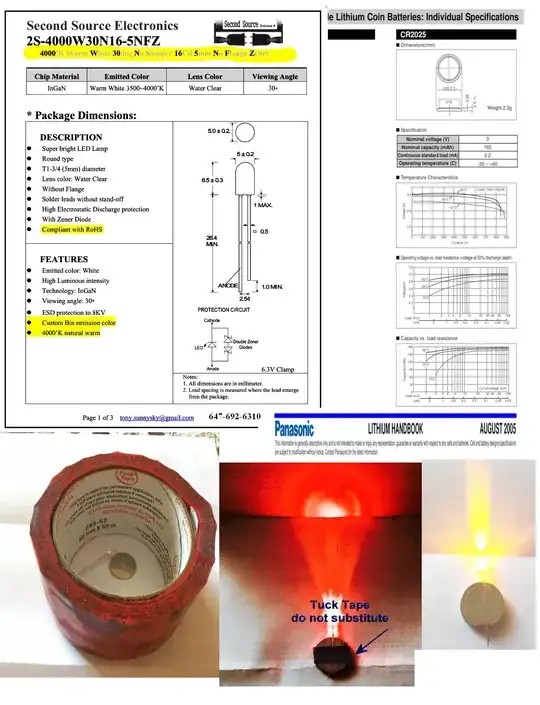

I need some help understanding the wiring of discrete LEDs. Typically discrete LEDs are rated for 185 mA at 2.7 V. Calculated wattage will be roughly 0.5 watts.

I want to make a 100 W panel which means 200 LEDs. I understand that LEDs should be driven by a constant current source but it will be highly impractical to put the entire set of LEDs in series and drive using a CC power supply. The voltage requirement will be roughly 540 V.

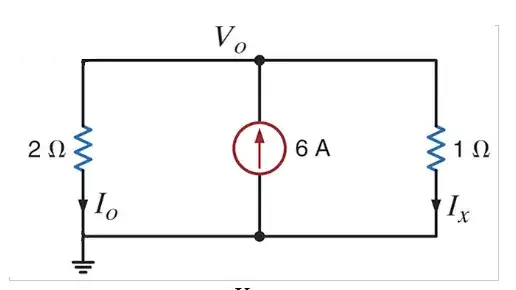

The second option is to connect the LEDs in a series-parallel network that looks like this:

8 LEDs in series and 15 such series networks in parallel. In an ideal case, this setup can be powered up by a constant current source of 4.625 amps (assuming equal current distribution in the parallel networks). I guess they use a very similar circuit in the chip on board LED lights (shown below):

My questions are as follows:

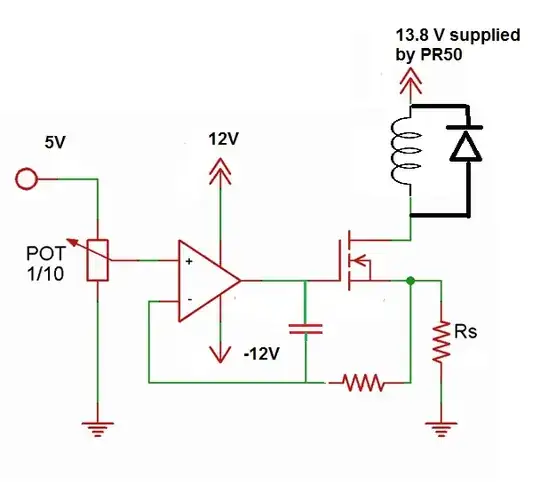

Can I just connect a 4.625 amp constant current source on red and black wires and expect the setup to work correctly?

Should I regulate the current in the individual series group network to 185 mA and feed the whole setup with a constant voltage power supply?

How do COB lights distribute the current so uniformly that they do not need current regulation in individual series group?