There are already plenty of good answers, but I have not seen any which includes some experience from the domains which deal the most with your issue so here are my two cents.

I am a satellite mechanism designer, local specialist for electronics within the team. I have been involved in a well-known mission relying on a Martian rover, and we had to tackle these issues with extreme temperatures.

I cannot talk for those who designed Supercam, but on Mars just as in orbit, "heating up" is not some kind of hacked-up patch in case the environment is too cold: this is the baseline. Only the components which absolutely cannot be heated up to temperatures within their operational temperature range are insulated from those which are, and properly passively (preferentially) or actively cooled. The reason is that cooling is much more complicated than heating (which only requires heater control loops), especially for active cooling (which basically require high-tech fridges with special heat pipes + fluid). So, generally speaking, the temperature of all electronics is directly or indirectly heated up, unless specifically required not to – for infrared imagery frontends for example.

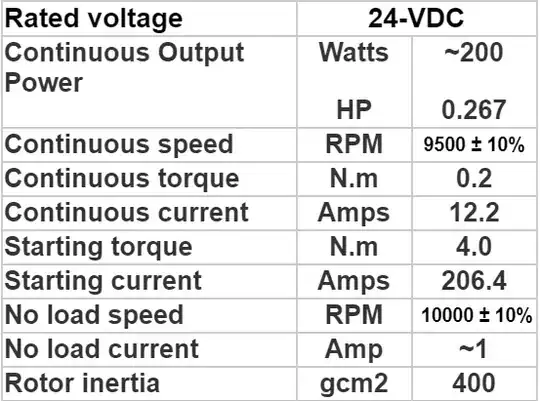

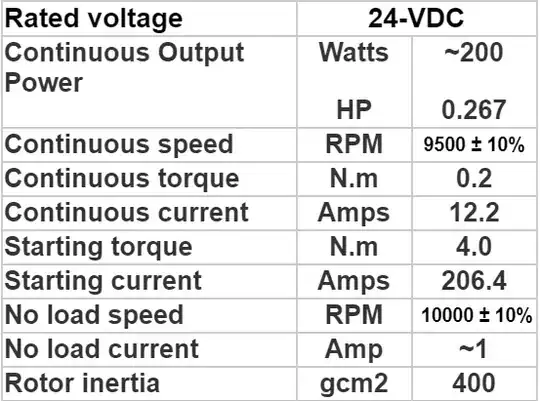

Therefore, for the majority of electronics, the issue rather lies in the non-operational temperature. We had to switch from an electronics-based integrated position sensor to an electromechanical position sensor acquired by an electronics acquisition system located further inside the rover because of this: the component we wanted to use only went down to −55 °C and the manufacturer did not recommend initiating a qualification campaign to test its survival to −130 °C (which, I think I remember, was the coldest temperature measured on Mars plus −15°C of qualification margin, see figure below for margins scheme as per ECSS standards [more below on that]). Generally this issue is difficult to tackle because all platform and payload equipment are switched off before commissionning in operation (except sporadic health checks) to save power while power generation is not yet on (solar panels deployed and tracking, radioisotope generator switched on, etc.).

In your case, I do not think you have these restrictions – so your temperature control system may be on from the beginning of the flight. You "just" have to make a proper thermal analysis (as accurate as you can with what you have, of course) in order to estimate the power needed to warm up your components to bearable temperatures, considering all radiative (from Earth's albedo, the deep space black body temperature, and temperature gradients on the balloon itself), convective (depending on what you mean by very high altitude), and conductive (on your balloon) paths. The more you will use highly reflective of emissive paint or surfaces, the more you will need heating – but the less hot you will go during hot cases. For unpainted mechanisms components in geostationary orbit, 5–10 W average per critical zone is generally enough, for example. The range of the temperature in the satellite itself is actually much narrower that we would think, thanks to conductive interfaces averaging the heat flux from all faces – so that is where most of the electronics is located. Here is an example of finite element analysis modelling on a random satellite I found on the web, but you can reach some pretty accurate results using thermal network modelling as equivalent electrical models (using thermal resistances, specific heat capacitors, voltage sources for temperature boundaries and current sources for power injection).

In a nutshell:

- Assume a component cannot be used at a temperature outside of its non-operational and operational ranges, unless you are ready to test it thoroughly (as part as some "qualification" campaign) at the required temperature extremes, with some margins. For components which are not dead-simple, it will be necessary to define in collaboration with the manufacturer the required tests, sequences and conditions of tests, to ensure the qualification campaign actually proves compliance of the component to the desired temperatures (some issues may not be understood by the user, or some others may arise randomly).

- Do not neglect thermal analyses, however crude they are. Place your components in function of the results and iterate, so that you achieve compliance with all operational and non-operational temperature ranges passively as much as possible (using coatings and paints if necessary). Favour being too cold over too hot – place heaters whenever necessary and wherever the most efficient, and design the temperature control system according to the thermal analysis.

Note that if the components suppliers are following the same standards (one would have to check the associated MIL-STD to be sure), if the rated temperature is −55 °C op, it means at least one unit made it down to −70 °C, which for electronics is not really far away from −80 °C (for mechanisms, thermal expansion could eat up a gap and jam well within ±10 °C). Pay attention though that a rule of thumb is electronics life/reliability figure is halved every 10 °C in hot cases –so I would expect it to be similar when cold as well–, and that all kinds of parameters that you checked before selecting the component will still need to be re-assessed taking into account any sensitivity to temperature. All of this is generally not worth the trouble compared to heating.

For more information on guidelines specific to the space domain, look up the ECSS standards – these are the standards we need to comply to when working for the European Space Agency, and generally for any european customer. ECSS-E-HB-31-01, ECSS-E-HB-31-03, and ECSS-E-ST-31C come to mind.