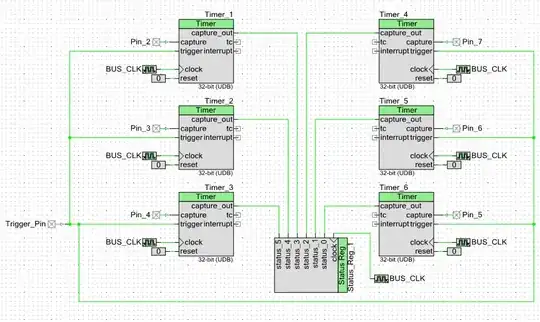

I have an n20 DC motor which has a gearbox with a 55mm m4 threaded shaft (see image below for visualization of the motor). I'm compressing a spring with this motor, so the motor needs to work relatively hard to compress the spring.

I am noticing that the spring compresses significantly less (3/4 the expected compression) after the 2nd or 3rd subsequent time that I try to compress the spring (I take about a 1 minute break between runs). I am noticing that the motor is slightly warm after 1 or 2 of these spring compression runs.

Is it expected to see such a large difference in spring compression?

Also, does the motor wear out over long time of use? I have been using this motor for about a month and am wondering if all of this use is causing degradation?

I've attached an image of the specs of the dc motor. The gearbox has a reduction ratio of 1/52 and I am using the 6V motor. You can see our motor's specs highlighted in red.

Could it be that the m4 motor shaft is wearing out over time and causing friction as a result? What about the m4 insert I am using (could that be causing friction over time)?

Here is the spring we are using: https://www.mcmaster.com/9657K371/

Thank you very much for the help.