I have a 5m LED strip (Ultimate Fancy LEDs) that consists has 30 LEDs per meter of WS2812B chips. Is uses a SP601E Bluetooth controller and was delivered using a 5V/6A power supply. Out of the box, the strip and controller works fine.

What I want to is the extend the wire (about 3m) from the controller to the actual strip. This is to be able to have the strip in the roof and the controller (with buttons) at the floor (so the kids can use it). The problem comes when I try to dim the strip. When changing from 100% brightness, the strip starts to flicker. My analysis is that data wire (that runs at 800kHz) is to long for the controller to being able to properly drive those extra meters. I tested a few different cables but can´t really get it to work properly.

- Using a typical 3-wire power cable (1.5mm diameter wires)

- SFTP network 4 pair network cable, AWG 26 where 5V supply uses 3 conductors, 4 wires for GND and 1 for DATA. In this case the voltage drop is a bit to much, losing about 0.5V over my 3 meter wire. But still this does not work properly for the DATA.

One weird thing though, is that the flickering is worse further down the strip (regardless of cable choice). I don´t really see this issue at the first meter of strip. If this is a signal integrity issue of the data line, I should see this an the entire strip, right? If I just get a good waveform to the first chip, the WS2812B should reshape the signal after each chip, right?

So, am I having power issues or signal integrity issues? I will later next week see if I can get a scope and measure some signals/voltages and get some more info. In the case of signal integrity, would adding a simply buffer/line driver do the trick?

Update 1: So it seem to be related to signal of data line and not power. Tested both supplying the strip at both end and this improves the “yellowness” of the end of the strip but does not change the flickering. Also tested with huge cap at beginning of strip, no change.

Also tested to add 220 ohm resistor before cable, things go much worse. Not only flickering but color change as well. Can’t really see that the data line degrades much over the cable (just some softer edges).

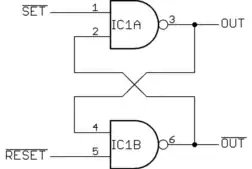

When it comes to the flickering, what actually happens is that the strip does not turn off but actually turns the leds brighter. I see a small voltage drop on the power line when it happens. If I short the data, basically don’t run it through my cable (so only power and ground in cable) things works fine. So the cable must cause the data line to violate some parameter (rise/fall or high/low time). I’ve ordered some buffers to see if this improve things...

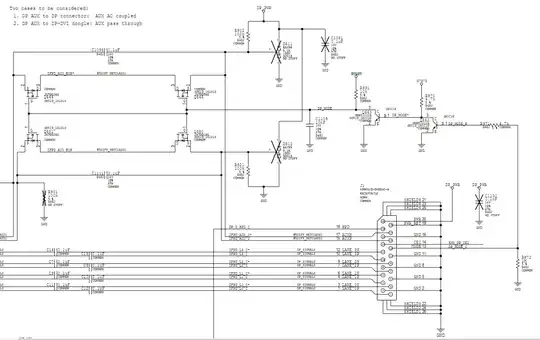

Update 2: Added a scope picture with comparison of the controllers 2 channels. CH1 has my extension cable and a led strip attached. CH2 is unloaded (so should be close to ideal).

I now realize that the controller high output is somewhere around 3.7-3.8V. When dimming the strip (and not drawing so much current), the supply voltage is at 5.34V. For the WS2812, high is 0.7xVdd which is 3.71V. Potentially the insertion of my cable, scales of that tiny margin. Plan is to test a level translator tomorrow to get the data line up to 5V.