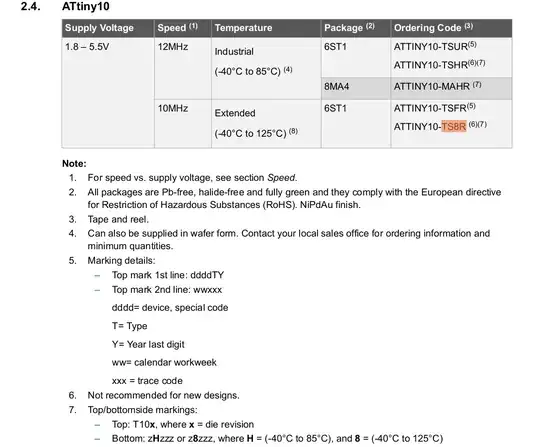

I am making my own circuit and I am using ATtiny10-TS8R (I couldn't buy any another type for now), but I found (6) in the datasheet on the part I want to use:

As noted in point (6), it says "Not recommended for new designs".

I used it already and the circuit worked very well, but I am willing to go to mass production, so, is it safe to use that one (TS8R) or may my circuit face problems in the future?