As an introduction to electronics, I am following Charles Platt's Make: Electronics (2nd edition).

Every circuit worked as expected, until Experiment 17: Set Your Tone.

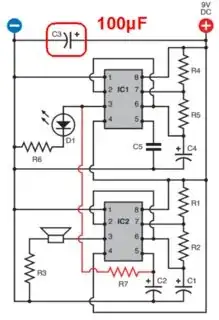

In circuit on figure 4-37 (page 163), two 555 timers are used in astable mode (as oscillators). The first timer (low frequency) output is wired to the control pin of the second timer (audio frequency), as to generate a siren sound... at least supposedly!

Minimal example

I have been facing different "surprising" behaviours with this circuit, and while trying to work my way out of this situation, I extracted the minimal example below:

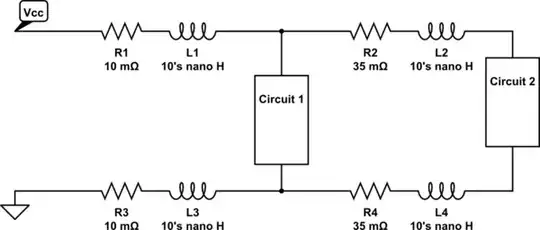

This circuit is two 555 timers in astable mode mounted as separate sub-circuits on the same breadboard. (I call them separate because, as far as I can tell, they only share the power rails). The left timer should have a frequency ~1/10th right timer (thanks to the left discharge resistor being 100K, compared to 10K on the right)

This behavior is what I observe if I only provide power to one timer at a time. But if I connect both at the same time (as shown in the picture above), then something I cannot explain happens:

- They both start flashing in sync, at a high frequency (but not exactly the second timer frequency, something a bit higher).

I cannot see how those two separate sub-circuits can talk... And from my understanding of experiment 17 in the book, they are not supposed to.

Questions

Is there a malicious being living inside the breadboard, and how should I name it?

Otherwise, what is the rational explanation behind this behavior?

Additional details:

- I provide 9V via some universal transformer which provide quite stable voltage.

- The timers are marked

99AG7ZM NE555P - The ceramic capacitor in series with the control pin is 0.01μF (marked: 103), as recommended by the book.

- The electrolytic capacitor is 10μF 25V

- I tried replacing both timers with other timers (exact same model), resulting in exactly the same behavior.

- Initially, I built the two sub-circuits very close, and tried another build with more distance (as the pictures in the post).

Measures

Measuring the voltage across the electrolytic (timing) capacitor gives a value oscillating between ~3.1V and ~6V on each sub-circuit, which is exactly what is expected. It is true when only one sub-circuit is connected to the power bus.

Measuring the voltage of the same capacitor in the left subcircuit when BOTH timers are connected to the power bus gives a stable voltage ~3.27V (barely oscillating between 3.265 and 3.275). I cannot explain that either (yet I do suspect this is all the same problem).