So I am interpreting this as options that don't involve crimping. I take it you don't insist on soldering.

Insulation displacement connectors (IDC) are an option for small gauge signal connections. As long as you use the appropriate wire they work pretty well. For example the CR series from JST interconnects with PH series connectors which are very common. When people say "JST connector" they are probably talking about the PH series.

The way these work is you just shove the wire (without stripping the insulation) into the connector and the little teeth on the connector cut through the insulation and make contact with the conductor.

http://www.jst-mfg.com/product/detail_e.php?series=38

These may not work for wire-to-wire applications.

You can also often buy pre-crimped wires for pretty low cost (check aliexpress, amazon, ebay, etc). You can just keep a supply of them on hand in a few different lengths and trim them to length as needed, or use them full length if they need crimps on both sides.

If you are designing boards, you can consider using screw terminals or push-in terninals instead of headers to make things easier.

Another no-crimp and no-solder option is wago luminaire disconnects. Not exactly what you are looking for but could be of interest. https://www.wago.com/us/wire-splicing-connectors/luminaire-disconnect-connector/p/873-902

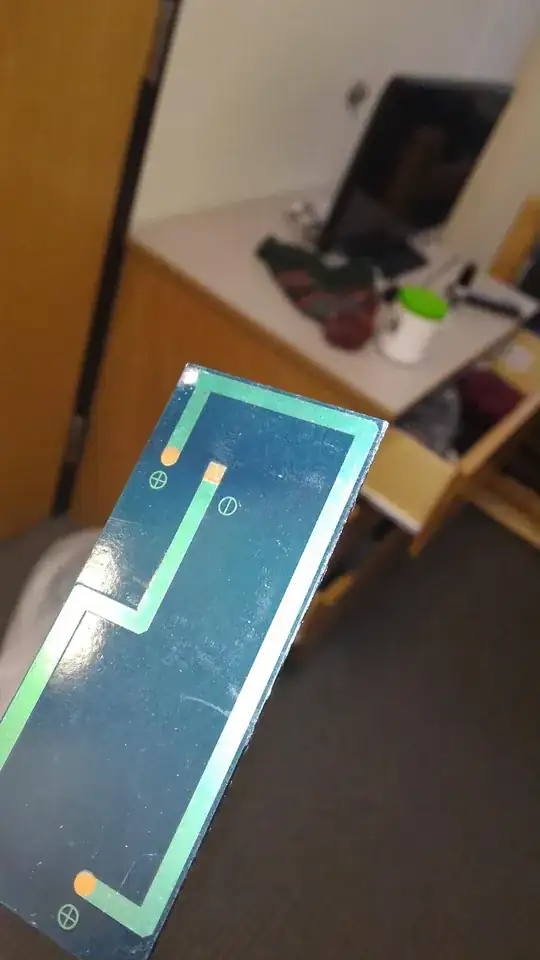

The last possibility I can think of is the wire-to-wire lever connectors. I am not sure if any big brands produce these. This link is likely to go bad over time but I think if you search for "wire-to-wire lever connector" or something similar you might find them. These seem to have no UL or other safety/compliance ratings. So probably best to use them for low power low voltage DC only.