@Andy provided few points to ponder, study and experiment with.

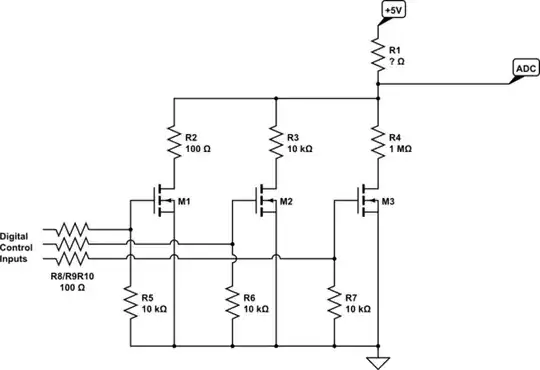

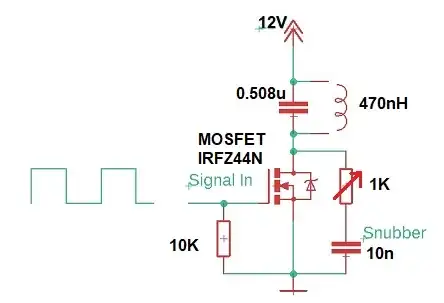

I took few days to study driving mosfet in linear fashion and then applied suggestions of @Andy to my circuit. Added 4.7ohm resister to source and added a 47ohm drain resister before LC tank.

I provided 330kHz sine wave from my signal generator but 22vpp could not be achieved at input due to limitations of signal generator. This generated following source to drain switching wave form.

Although its not a perfect sine wave (yellow) yet its very much clean from ringing noise. Blue signal is received at Rx.

Following is the signal across tank circuit. The vpp at yellow signal is 1.64V only.

Although its not a perfect sine wave (yellow) yet its very much clean from ringing noise. Blue signal is received at Rx.

Following is the signal across tank circuit. The vpp at yellow signal is 1.64V only.

To increase to signal strength i removed 47ohm resistor between supply and tank. This caused a rise in Vpp of transmit signal.

The circuit worked at 47ohm and lower values but ceased to switch at higher resistance values.

The reception of this transmitter was very clean as appears in blue signals. It sensed stainless steel forcep with very small rise in amplitude. This was not happening in my previous attempt.

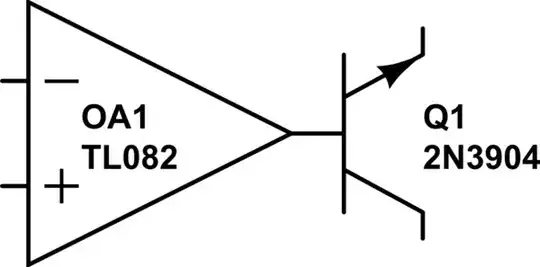

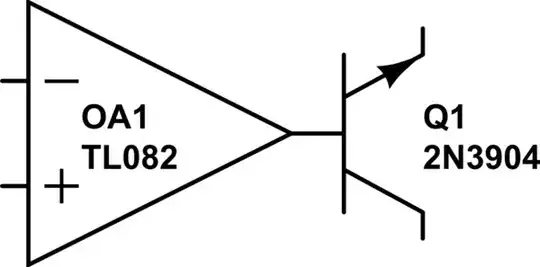

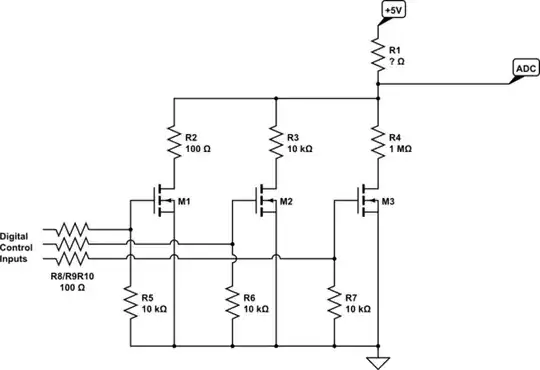

I used a push pull driving circuit mentioned here.

Designing a *linear* MOSFET driver stage

But it did not serve my purpose.

I could not find C0G class I ceramic capacitors in local suppliers. I shall manage to source them soon.

The question is

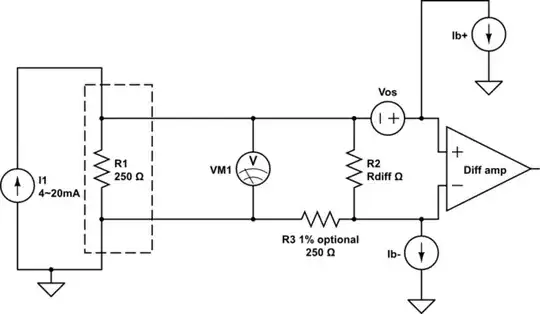

If both rx coils cancel each other why am I getting a signal of few millivolts and how to increase sensitivity of system to sense 2mm object of any metal?

I don't know if its appropriate to ask another question here or should I start a new thread.

Although its not a perfect sine wave (yellow) yet its very much clean from ringing noise. Blue signal is received at Rx.

Following is the signal across tank circuit. The vpp at yellow signal is 1.64V only.

Although its not a perfect sine wave (yellow) yet its very much clean from ringing noise. Blue signal is received at Rx.

Following is the signal across tank circuit. The vpp at yellow signal is 1.64V only.