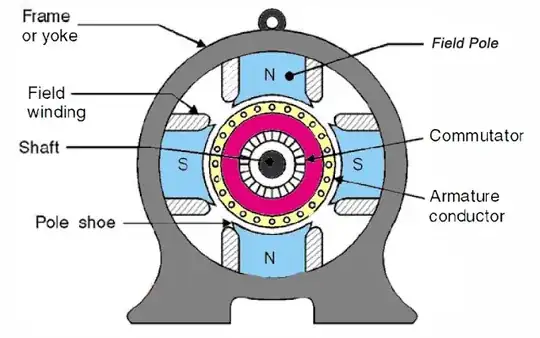

Theoretically it won't make a big difference. A single winding of wire will generate a magnetic field with north and south just as well as two windings oppositely placed will. Practically, you'll get a slightly smaller diameter motor when windings are distributed around the stator because putting all the turns on one side means more volume in that area.

You might not get the same magnitude levels (due to flux leakage) as you would with distributed coils but that all depends on how large or small the magnetic permeability of the stator is.

For machines with more than one pole-pair (the OP's drawing has one pole-pair) you might lose the simplicity of a solid and continuous stator magnetic yoke because to achieve N-S-N-S will require a magnetic field interruption between N-S and the next N-S. This assumes coils are wound on the N pole with no coils on the S pole. Therefore two significant gaps will be required and you might now lose the physical stability given by the yoke: -

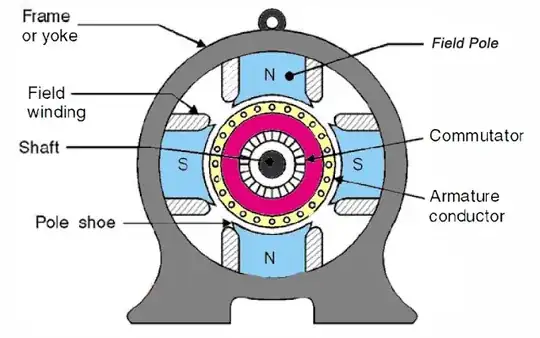

However, it might work with a continuous yoke and coils only on the N pole faces. I guess a multipole-pair might work with coils only on the pole faces marked N below: -

Naturally S poles will form on the unmarked pole faces so it's doable. The devil will reside in the detail of course.