I'm designing a project that is going to work on a flying quadcopter. It features an ATmega328P MCU in the main 5V circuit, and is powered by a small (<500 mAh) 1-cell LiPo battery. I want to provide low-voltage cutoff mechanism to protect the battery. Currently I'm considering the three options:

Just let the main MCU to monitor the battery voltage, using VCC as reference. VCC is usually 5.1 V, but to be sure I will also need to measure own VCC.

Pros: no additional circuitry. Can signal cutoff reason using a LED. Configurable cutoff voltage. Soft cutoff.

Cons: in case of malfunctioning of the main MCU (software bug) the battery voltage may be left unobserved under a high load. Complicates software. Requires powering the 5V network.

Use a Reset Monitor like MAX809. Power-down current is 0.5 μA.

Pros: highly reliable.

Cons: no signalling. Not easily configurable. Hard cutoff only. Additional circuitry (voltage divider).

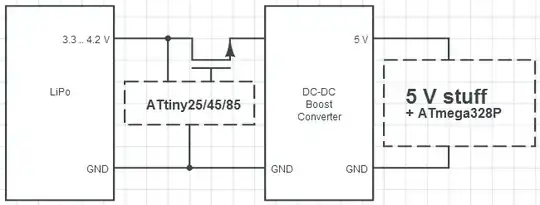

Use an intermediate MCU like ATtiny25/45/85. It is tiny but can measure own VCC. Power-down current is 2 μA.

Pros: signalling. Configurable. Easy to test. Measures voltage before powering other things. Soft cutoff (can signal the main MCU that it's a time to gather stones).

Cons: requires additional (but very simple) software. Weight (1g?)

Option #3 is illustrated here:

I'm thinking of going with option #3. Does it make sense?