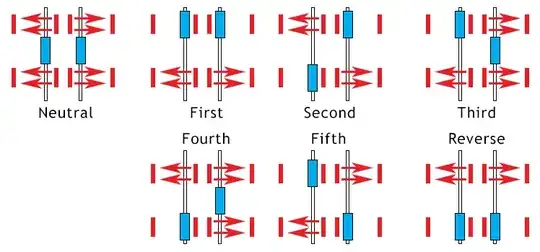

I drive all Manual Transmission vehicles, and after a long battle of wills with my girlfriend, she has conceded that she would learn if there was a display that showed what gear was selected, thinking this might deter me. To her future dismay, I have an Arduino and I'm not afraid to use it.

So here's what I want to build: a small bracket that will fit nicely under my shift boot and relay enough information to the Arduino to determine the position of the shifter. This is different than some methods that try to infer the relationship by RPM and speed, as they cannot work when stopped or with the clutch in.

Ideally, I do not want anything touching the shifter. I could use two (or four) spring potentiometers, but they are $122/each or more! Plus I don't want any tension or touching of the shifter. I could use microswitches, but they may eventually get weak or be very sensitive to the bracket position, and would still touch the shifter.

Hall Effect

What I'd like to use is either Hall Effect Sensors or Proximity Sensors. Hall Effects are cheap (~$0.25 on eBay), and I'd prefer to use them. Would they be sensitive enough to pick up the shifter moving close to them? Would they continue to sense the presence, or do they only sense movement? Would I have to magnetize the shifter? Do I want Latching ones? Could someone explain how to use these in a manner that the Arduino can sense, and/or provide a diagram for this?

Proximity Sensors

The other option would be Proximity sensors, which look to be about $22/each at the cheapest, so buying six would be pricey and not fit well under the shift boot. Would these work without magnetizing the shifter?

Are there other options?

Edit

I'm now between using microswitches and the cheap hall effect sensors pictured above. Could someone familiar with HE sensors draw me up a simple wiring diagram for how best to wire one to an arduino? They say they'll sense 5-8mm in distance, so this should be enough as I'll be mounting them near the base of the shifter shaft. Also, what magnet(s) should I use on the shifter? And help on how many / what strength I'll need?