I'm trying to put together a home automation solution for my newly built house. I'm very new to this, specifically for hardware matters and asking this question to verify if my understanding of what I've learnt from internet is more of less correct and an advice on how to move on.

I have decided that I will separate the whole thing into three "layers" - sensing, alarming and control. The question is regarding the first one. I put sensors on my floor plan and it counts 60 environmental sensors (temp, humidity, light, movement, moisture) and 40 security ones (smoke, movement, gas, distance, vibration, magnetic contact).

There are two general options I have figured - 1-wire and CAN-bus. 1-wire is relatively simple and there is lots of information on this on the internet and many projects to learn from. But since all the sensors are passive it looks like 1-wire is good for collecting data from temperature, humidity and alike sensors. But doesn't quite well work for light and movement sensors for instance - if you want to know if there is movement right at the time, you'd have to "question" those sensors pretty much as frequent as you can generating a lot of garbage traffic. 1-wire is relatively cheap, too, and requires very little soldering - just making sure 3 wires are wired correctly, even a kid can do this.

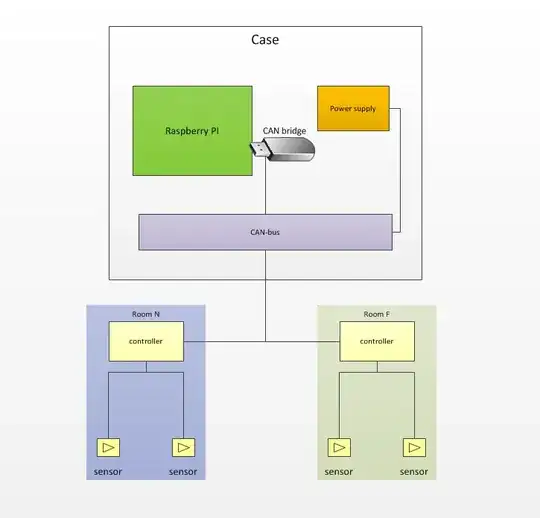

CAN-bus seems to contain more possibilities but is as well harder to understand and it's not easy to find sample home automation projects that will explain everything in enough detail. But if I understand it right, since you are able to have a main device and child boards connected to it, the sensors on the child board can be active and trigger signals to other members of the network without involving the main controller device.

If CAN-bus is a good way to go, can someone point me to affordable devices in the field? Like boards that you can connect sensors to and so on?

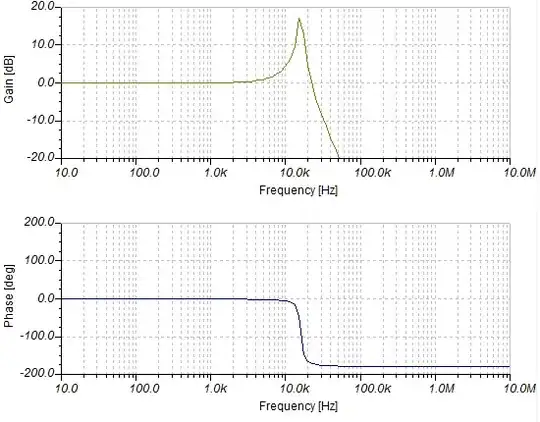

Here are two pics of topology layout for CAN/1wire - am I getting it right?