I want to repair my computer mouse cable which has become disconnected from the PCB. The wire is insulated with enamel and I have to remove it before soldering it back onto the board.

How should I remove the enamel?

I want to repair my computer mouse cable which has become disconnected from the PCB. The wire is insulated with enamel and I have to remove it before soldering it back onto the board.

How should I remove the enamel?

Common ways of removing the insulation on enameled wire include:

Get a pill of aspirine. Put your enameled wire on its surface and press it down with a soldering iron's tip heated by operational temperature. Aspirin melts, boils, gets in contact with enamel and desintegrates its coating on wire's copper. So you can strip it with the same soldering iron's tinned tip pretty easily in a couple of seconds (up to 10 sec in fact). Then let it cool down for a several seconds and remove the brittle (like a colophony) melted aspirine's rests away from naked and tinned enameled wire's tip... Do not breath in the aspirine smoke.

I'm surprised no one has mentioned magnet wire strippers. They're handheld motorized tools that give you a perfect strip with a sharp edge every time. They're adjustable over a fairly wide range, the ones I can find all seem to strip magnet wire between 0.3mm to 2.5mm in diameter. That won't help you if you're using 30 gauge or smaller magnet wire, but 28 gauge and up can be stripped very nicely, quickly, and effortlessly with one of these tools.

Just do a google, amazon, or ebay search for magnet wire strippers and you can find them fairly easily. They all seem to be essentially the same product, down to the model number (DF-6). They typically cost $50-$60, so they're certainly not for everyone. I think most hobbyists would find themselves hard-pressed to justify the cost. But if you need to strip a lot of magnet wire, these can save you a ton of time and effort.

Also, if you need precision magnet wire stripping capability (you people know who you are), then there is a much higher end tool for stripping magnet wire called a rotary collet stripper.

They cost $700 to over $2000 and if you need one, it is probably safe to say you already know about them, but I figured I might as well include them too.

If you are only doing this for a few wires (assuming USB or PS/2, that's only four to 6), just scrape it off with a knife, or use some sand paper (or even an emery nail board).

I had to strip 60 ends of 0.2mm enameled wire for my little project of dead-bugging and dumping a 32-pin EEPROM:

By the end I arrived at a method of laying the end of the wire on a piece of smooth wood, and scraping the enamel off with an edge of a thin fine file. It's not as sharp as a blade would be, so you don't damage the wire so much, and you can control the length of stripped area better than with sandpaper.

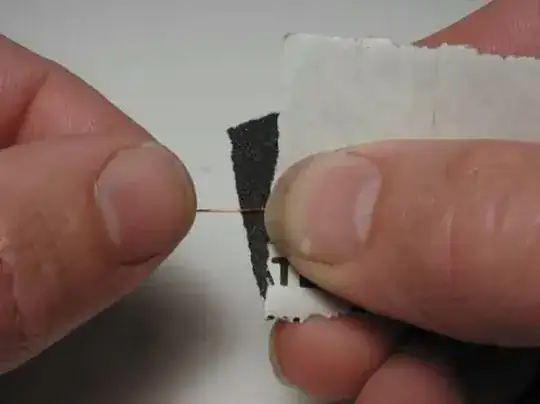

Since I had to strip short pieces, it was hard to hold them against the pull of the file, so I made a little holder by gluing two pieces of fine sandpaper to the inside of a clothes peg:

Hydroperitum (Hydrogen peroxide - urea) can be used like aspirin. But it is less smell and soldering is much more comfortable. Use it like resin. 1-3 seconds is enough usually.

Put the enamelled copper wire in 98% sulphuric acid and wait 10 minutes. The coating lifts and floats away. At least, this works for 'Block' brand copper wire whose coating (I think) is polyurethane.