I misread the question. I had in mind that you wanted to replace an aluminum capacitor with an MLCC.

What you are considering is replacing an MLCC with an aluminum capacitor.

Don't.

The leakage of the aluminum capacitor is almost guaranteed to be higher.

ESR isn't what defines the leakage current.

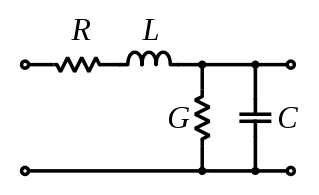

ESR (equivalent series resistance) is like putting a resistor in series with an ideal capacitor, while leakage is like putting a resistor in parallel with an ideal capacitor.

The datasheet you linked gives an insulation resistance of 50 ohms F. Take 50, divide by 10 microfarads (as farads) and that's the resistance of the insulation. That works out to 500000 ohms for your 10uF part.

At 1.8V, that's about 3.5 microamperes.

You need to find an MLCC with a higher insulation resistance.

The one I picked before for comparison says 100000 Mohm or 1000 ohms F, which ever is larger." For a 10uF part, that'll be 100000 Mohm because the ohms F is smaller. The leakage current is then far below 1uA.

You can reduce the leakage current by using a better MLCC. Aluminum capacitors don't get much better.

Incorrect answer. Leaving it here for the comparison of MLCC to aluminum capacitors.

Picking the datasheet for an aluminum capacitor at random, I find a maximum of 3 microamperes. That's in the same ballpark as your 10 microamperes so it looks you have a reasonable measured value.

Picking a datasheet for a 10 microfarad MLCC capacitor at random, I don't find leakage directly given. It does give a value for "insulating resistance," which I take to be related to leakage current. At 100000 megaohm, the leakage will be lower than the aluminum part at any rated voltage.

The MLCC won't necessarily give you the same capacitance, though. You may need to use a 20 uF or more rated part to guarantee the same capacitance at your operating voltage. Ok, you are working at 1.8V, so the loss may be lower than usual. You should still consider it, if only to look at the datasheet voltage derating curve and think "nah, doesn't matter."