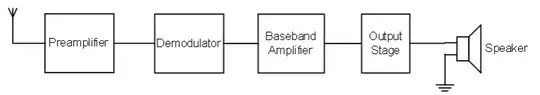

As part of a current-to-voltage preamplifier that I'm working on improving, I'm trying to model the current source of an scanning tunneling microscope (STM). The way it works is described below (based on my understanding), with the block diagram shown below. Given a material sample, it is biased at some voltage level. The STM has a special tip, and a current passes through the tip from the biased sample, with the STM using that current measurement as a way to view the surface of the sample. The tip starts at X=0, and it moves up/down until the computer measures a specific current. Once it sees that current, it moves on to X=1 (or whatever the next point is) until it reaches the end. Think of it as scanning in a grid-like motion.

simulate this circuit – Schematic created using CircuitLab

This block diagram may be more complicated than I'm making it, but this shows the rough idea of how it works based on my understanding. That tip current is converted into a voltage for measurement later on. In LTspice, I was simulating the current as an ideal current source, but how do I model the parasitic capacitance between the tip and the sample? Is there a standard value that is used to model the parasitic capacitance, or does it vary?