I have always wondered why there is an opening in the solder mask whenever a microstrip line is laid out on a PCB.

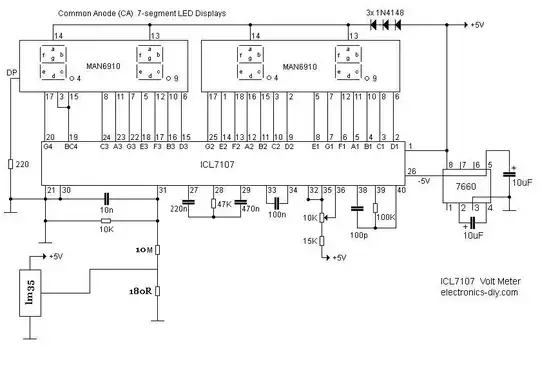

For reference consider the following board:

There is clearly a large opening in the board around the microstrip lines and stubs.

Does it have something to do with avoiding to change the characteristic impedance of the line, or does the solder mask somehow effect the propagation in the microstrip line?

I have searched but could not find a clear enough answer.