I used to take TVs apart for fun (and parts, and learn.)

Some of the degaussing coils were beautiful -- nice, thick copper. Others were made out of aluminum wire. If I were engineering it, though, I would not have even thought of aluminum wire.

Can anybody shed some light on the thought process behind this? (You might relate how you have used aluminum wire in your product.)

I think "light" might sometimes be a reason (but probably not in the case for TVs with the big and heavy legacy CRTs).

I am after the engineering (or design) thought process here.

For those beginners or young ones who don't know, a degaussing coil is a coiled loop of wire, I'm guessing 40 to 75 turns (technically around an air core) held tightly together with electrical tape. The old cathode ray tubes would slowly get magnetized and exhibit a bit of "rainbow" or discoloration -- or if you had a child (like me) with magnets. ;-) The degaussing coil would remove the magnetization by a slowly decaying AC pulse.

Here are some sample pictures:

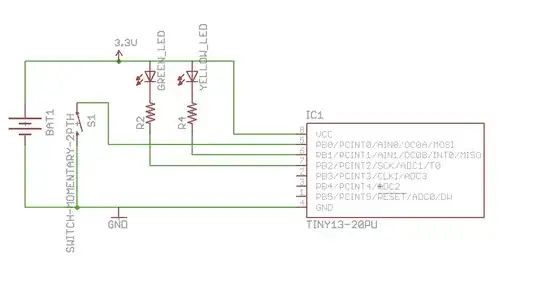

Example picture #1:

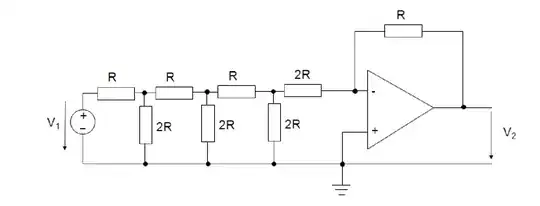

Example picture #2:

(I took everything apart because I wanted to learn how to make my own products some day.)