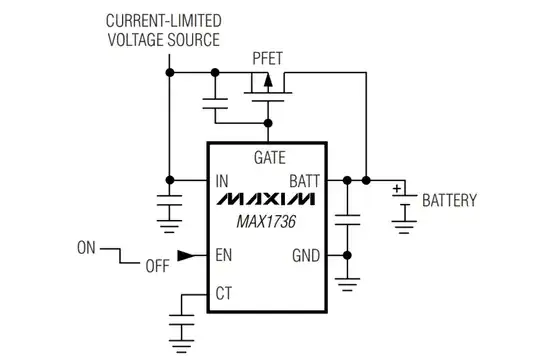

I am searching for a schematic or design that would help me charge a very small 1mAh 3.7V LiPo battery. I've done a pretty thorough search and the closest off-the-shelf IC I can find provides 10mA minimum current. My LiPo is only rated for 0.5C-1C charging, so ideally I'd like to charge it with 0.5mA max current to be safe. I've already tried using a really large resistor attached to the standard PROG pins of various LiPO charging ICs, but it doesn't work because 1mA is so much lower than the minimum 100mA. I have not tried with the 10mA charging IC, but I imagine similar behavior could be expected.

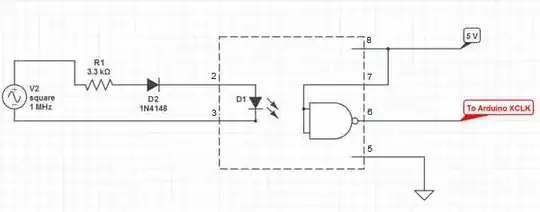

One thought I have, is potentially using the 10mA minimum current LiPo charging IC I found here and connecting a constant current sink to the output, set to sink 9mA or so. I believe this may interfere with the chip's auto shut-off feature though and cause risk of overcharging. There may be a way to add some shut-off logic based off of the CHARGE output of the IC, where I could shut off the current sink thus shutting off the entire circuit.

I really hope that creating a LiPo charger from scratch is not necessary. However, I have minimal experience with electronic design (primarily software engineer) so I am not sure how difficult or not this would actually be. I am able to create and route PCBs, but to do so I need help with a schematic to accomplish this 1mA peak LiPo charging current and this is what I am struggling with. Any help here would be greatly appreciated!