Here are some points that I remarked on your schematic

What is the minimal set of parts for a circut with this AVR microcontroller?

Atttiny and Atmega are from same family and I would recommend using pull-up on your reset pin. You are driving motor, then unwanted EM inteference is abound and your controller will most likely trip a reset bar. It wont be constantly held up by your programmer (I hope)...

Battery control section ignored as requested.

DC/DC Converter LM2596 is prone to oscillation in some cases, according to book Switching Power Supplies A-Z by Maniktala (easy to find book, but information buried in it somewhere). Keep an eye on this bugger if possible.

100k Resistor is there to provide current charging to Miller Capacitor that is present in MOSFET (inherent in construction of MOSFET). Some use it, some don´t depending on case. WIth Gate driver, I would give a small resistor 100R or similar, just to limit current flowing into MOSFET. Optimisation is desired after working prototype (check resistor thermal rating).

I haven´t done calculation on MOSFET disssipation, but answer from Andy aka "seems leg´t" so take care on thermal side here (heatsinks, heatsinks, heatsinks). If you want to avoid this you can just stack mosfets (as you did) to get sufficient power divider to lower dissipation on each. This is not elegant solution, but sometimes brute force is fun and good for learning.

I would put a pull down resistor on gate pins, to prevent any accidental "switch on"s during power up phase. I recommend 47k to 10k. No preference on any of those, just sufficient pull down to ground. 100k is not recommended as they can be considered "too weak pull down".

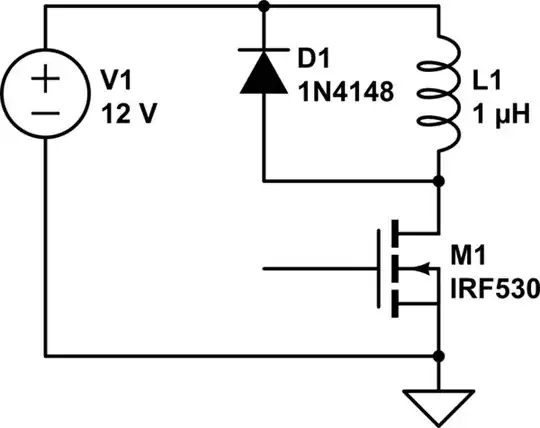

You need to have inductive kick-back diode present as well. Sure this was mandatory for BJT and you can get away without putting one on MOSFET because of "built-in" MOSFET body diode, but I always prefer to have my own components instead of hoping for built in failsafes.

Here is link to this discussion.

Where should I put the kickback diode in a transistor switch?

This was "back of envelope calculation and design" so let know if you need any additional information

Happy hunting and remember - safety first