Our vendor pulled some PCBA out of storage, been sitting for about a year.

They found about 5% delaminated. They claim it was 'because of the storage duration', but I'm not buying that. I think these boards were defective from day one.

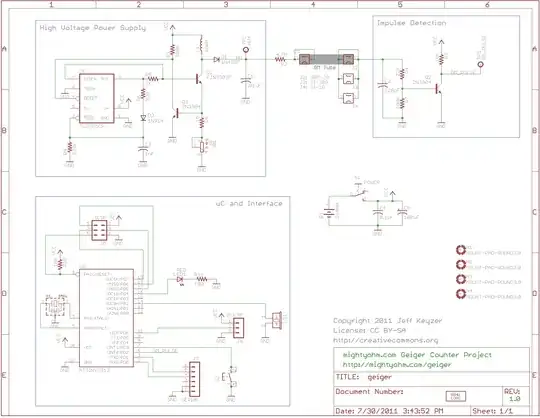

Yes, I know a hatched pattern for the pours is better - These aren't my design.

Anybody think this is a "storage" issue? They're (supposed to be) FR4, so presumably they are fiberglass resin, and shouldn't be hygroscopic. Vendor is in south-east China (Shen Zhen) where the humidity and temperatures are "jungle like" most of the year. I'm sure there was no climate control during storage, I wouldn't be surprised if they were subjected to months of 130F+ temperatures. Maybe storage EXPOSED the issue, but I don't like the theory it CAUSED the issue.

In field, these boards will get quite hot during normal operation. There's a number of high-power MOSFETs on the other side, and the board regularly will see 15A, sometimes much higher during surges (about 35A max or so)

Further, the vendor is suggesting subjecting the entire inventory to a heat-test, basically a shorter version of a reflow oven cycle, to ferret out the bad ones. They're suggesting use some kind of profilometer to detect the 'bubbles'.

This is a 4-layer PCB. We almost "never" use multilayer boards, and I doubt our vendor sees them often either (maybe "never").

This is also a 'safety critical' component.

Any and all comments & suggestions welcome!!!