What would be the purpose of using a colour code for resistors instead of just printing their values?

-

1@jsotola I'm assuming OP is indian and it has to do the way english is taught there. I find them using "doubt" as a catch-all word for "general lack of knowledge" instead of something specific they have in mind that they are uncertain about. – DKNguyen Aug 11 '20 at 03:39

-

1@Chuck problem with printing text on an axial resistor body is that the info would have to be printed at least 3 or 4 times to ensure that it could be read when the resistor was installed in a circuit board ... surface mount components have a top side, so it makes them a good candidate for printed text – jsotola Aug 11 '20 at 03:45

-

1Without the color code how would we know what bad boys do? (Not to mention Violet.) – Hot Licks Aug 11 '20 at 18:00

4 Answers

A long time ago, the technology did not exist or was too expensive to print such small text on parts.

Also, you can read coloured rings no matter what angle you are looking at the resistor from or how it is mounted, but as someone who has trouble telling similar colours apart this is useless and I don't really buy it.

- 54,733

- 4

- 67

- 153

-

17As someone in possession of old PCBs with lots of resistors with printed values, I can tell you that "read from any angle" is no myth. When the printed value is face down on the board, you have to remove the part (at least on one end) to read the value. Murphy's law almost guarantees that the value will be face down on every part you need to check. – JRE Aug 11 '20 at 06:01

-

5Many years ago, the Royal Navy blocked those with colour blindness from electronics positions on the grounds that (at the time) the ability to read colour codes was critical. – Peter Smith Aug 11 '20 at 11:09

-

3Back in the 30's and 40's it was very common for radio manufacturers to use "non-standard" resistor values (70k, 25k, etc). The urban legend goes that those values were chosen because the factory lighting was so poor that they used the ones with more distinct color bands. No evidence to support this, just a story the "old timers" tell! – 640KB Aug 11 '20 at 12:38

-

@640KB Back then though, there was no "standard". It wasn't until WWII that standardisation became important, and it wasn't until the 1950s that this was formally codified. – Graham Aug 11 '20 at 13:40

-

2Manufacturability is definitely the major reason. Even today nobody wants to pay 0.9¢ for a resistor if it can be had for 0.7¢ instead. Painting a stripe is a bit simpler than printing a tiny character, and you'd be amazed how much people really want to save those 0.2 cents. – J... Aug 11 '20 at 16:52

-

1@JRE When I say I don't buy it, I mean I don't believe that being able to view from any angle was the driving reason why text was not used. – DKNguyen Aug 11 '20 at 17:23

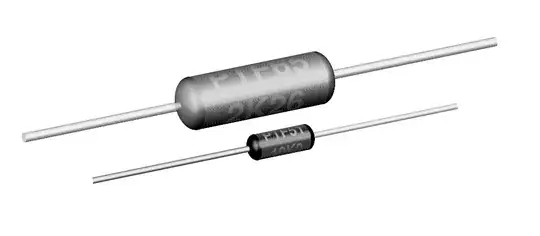

Some leaded resistors, particularly precision ones, are marked with the value.

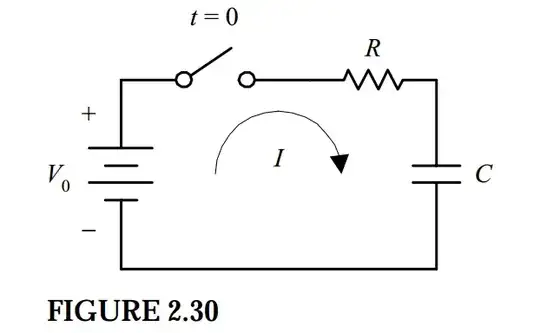

Putting color bands on the resistor allows the value to be read regardless of the orientation, and very quickly for a skilled person.

- 376,485

- 21

- 320

- 842

-

8Ah, I am a poor old hobbyist and I can "scan" colour rings 10 times faster than using a magnifying glass to read numbers and letters. Actually all my life I have not never seen any expensive resistor with marked value, because I am poor. :) – tlfong01 Aug 11 '20 at 03:09

-

1@tlfong01 My theory is that they think poor people are illiterate, therefore something must be done so poor people can read the resistor values. – DKNguyen Aug 11 '20 at 04:16

-

1@DKNguyen so poor people might be illiterate, but must necessarily be colorate :) – Ruslan Aug 11 '20 at 11:10

-

It's okay if you're assembling a board, but it kind of sucks when you are trying to read the value printed on the resistor, but it's on the side next to the PCB, and the board is conformally coated. – Spehro Pefhany Aug 11 '20 at 13:52

-

@Ruslan Ahhh, but you pass pass down coloracy to to future, poor and illiterate generations through song and dance via the nursery rhyme. – DKNguyen Aug 11 '20 at 18:21

-

-

@DKNguyen, well, I think the resistor colour rings is sort of universal communication protocol, based on colour coding, and not on any language. An example is the Green, Yellow, and Red lamps of traffic light. Whether you know or not know any language, you can also read traffic light. I sometimes wonder if we can even teach a smart guide dog to read traffic light for its blind master. – tlfong01 Aug 12 '20 at 08:02

-

@tlfong01 Dog's have very limited (dichromatic) color vision so that might not work too well with R/Y/G lights. They're smart enough though. As are pigs. I once saw a pig who could understand verbal commands and pick out matching printed number cards. – Spehro Pefhany Aug 12 '20 at 08:05

Once you go to more modern surface mount parts, it is more common than not to have the resistance value simply printed on the top for the larger (and thus more human solderable) sizes:

Through hole parts don't do that because they're old and in the old days precision manufacturing wasn't as good as it is now.

Surprisingly, this (edit: labeling) never caught on for capacitors (edit: SMD capacitors), even though resistance is much easier to measure.

- 14,842

- 1

- 21

- 43

-

3There were a number of vintage axial capacitors that used color bands to denote value, ["Bumblebee"](https://www.wdmusic.co.uk/images/luxe-woman-tone-capacitor-kit-oil-filled-022mf-015mf-bumble-bee-p13048-14367_image.jpg) (Bumble-bomb) for example. Some vintage mica capacitors used dots with a [similar scheme](http://www.tpub.com/neets/book2/3g.htm) too. – 640KB Aug 11 '20 at 12:54

-

Back in the day, used a lot of these [Philips film capacitors](https://projectpoint.in/image/data/100nf-100v-cc2.jpg). – Spehro Pefhany Aug 11 '20 at 13:54

-

@640KB Sorry, I meant labeling SMD caps never caught on. Always funny to see a bigger 1206 unlabeled cap but a microscopic 0603 with the resistance clearly written on it. – user1850479 Aug 11 '20 at 15:24

-

For quality control purposes it is important to have a marking as AOI is often the primary QC , of course tiny parts can't have this so advanced SMT tools will compare images of each part as it is being placed to known reference models of the part. This also catches upside down and backwards parts (when it matters) as every once in a while the part is in the reel wrong – crasic Aug 11 '20 at 17:35

-

1@user1850479 is it mostly a property of the material,l believe. Ceramic is either a more difficult or more expensive to label, industry would love labeled caps it's one of the biggest QC shortfalls for most manufacturers – crasic Aug 11 '20 at 17:37

In some OLD resistors I once rescued from tube radios as a kid, the BED_coded resistors were only readable from the top.

Because the code was

BODY color

END color

DOT color (only visible from the top)

- 33,703

- 2

- 18

- 46