I'm attempting to remove a BIOS chip from a Seagate Momentus 7200.4 HDD with a 100565308 Rev A chip number.

I've followed videos online, but for some reason the BIOS chip will absolutely not come off. I'm worried that I will damage the chip from scratching it up because of the tweezers slipping off.

To remove the chip, I'm using a micro heat pen rework station set to 300C.

Is there some general reason that this chip won't come off? Should I use some other chemical to remove it now that the solder is gone?

EDIT: Thank you all for the great information. To explain exactly what I'm doing, I'm attempting to restore an old laptop hard drive which has some burnt looking circuits on the chip. I happened to have a second working hard drive with the exact same model which originally came with the laptop, so I am using it as a donor drive to fix the broken one. I believe I just need to take the 8-pin BIOS chip off of the PCB, but it is giving me troubles as noted above.

My equipment is:

- Hot Air rework station: https://www.amazon.com/gp/product/B07XPG8VPG/ref=ppx_yo_dt_b_asin_image_o09_s00?ie=UTF8&psc=1

- Soldering iron: https://www.amazon.com/gp/product/B07RZV2DW8/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

- Solder: https://www.amazon.com/gp/product/B07VRCBJSZ/ref=ppx_yo_dt_b_asin_image_o03_s00?ie=UTF8&psc=1

- Flux: https://www.amazon.com/gp/product/B00425FUW2/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

I've tried the hot air gun at 370C briefly with no luck as well. I didn't try some of the other ideas that have been posted yet though

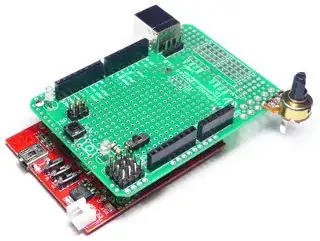

Here's an image of the donor chip - I'm sorry for the hairs all over it, I used a Q-tip to remove some flux with 99% iso alcohol and didn't see the remaining hairs at the time.