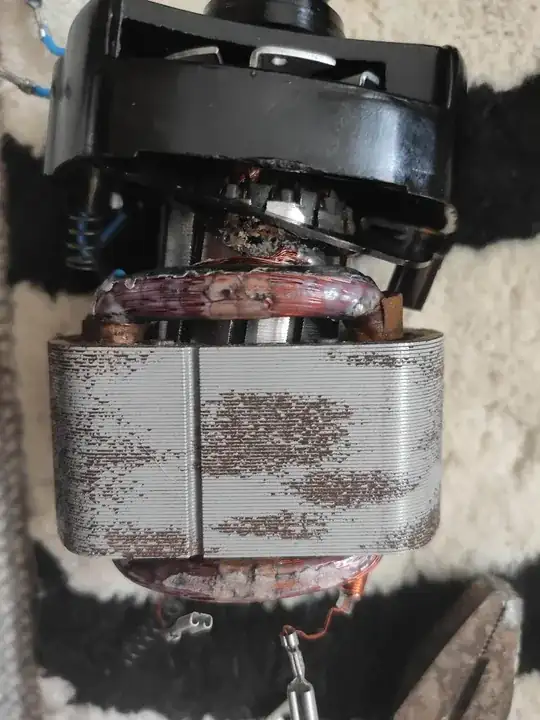

...the field coil wires are covered with a fine plastic film insulation, however this has perished in places. Could this be causing the issues, and if do what's the best fix please?

The only fix is to rewind the field. You will need to look for detailed instructions, information about the materials and a supply source. You may find that it is more profitable to replace the motor.

You will also need to make an evaluation of your judgement about the amount of material that can safely be removed from the commutator, the adequacy of your cleaning and preserving the slots and your skill in doing that work.

The capacitor is intended to reduce the electrical radio frequency interference caused by the sparking of the armature. The value is not very critical.

The motor is called a "universal motor." Use that search term to find more information.

The proper brush composition and springs are important, but perhaps not the most important issue in this case.

Shorted stator turns will cause the stator to overheat and vice versa. Not turning the motor off immediately if it stalls can cause the motor to overheat. Motor overheating can also be caused by failing motor bearings or other bearings in the machine. Also parts of the machine that are not moving freely can cause motor overheating. Possibly overheating could be caused by misuse of the machine such as prolonged use with fabric that is too heavy. In any event, it is important to learn how to determine if the motor has shorted windings. Examine the stator and rotor carefully for variation in winding color and learn how to measure winding resistance.

The winding resistance is quite low. It probably ranges from a tenth of an ohm to a few ohms. You need an ohmmeter with a scale that allows readings in that range. Having normal resistance data from the manufacturer would be best. For the stator, you should be able to get access to the connection between the two halves. That will allow comparison. For the rotor, the resistance between each pair of segments on opposite sides on the motor should be the same. The resistance between each segment and the one next to it may be too low to read, but they should also ne the same.

Be sure to check the resistance between the windings and the rotor and stator iron core to make sure the windings have not shorted to the core.

Update. This is the other end. It's melted on one side only. Looks very poorly.

Update. This is the other end. It's melted on one side only. Looks very poorly.