I'm helping a student at our art academy with an interesting project. She is building an array of peltier elements (let's say 25 to start with). She wants to control them individually using PWM and be able to switch the polarity on them every now and then.

We are aware this is a terrible idea in terms of thermal stress and the life expectancy of the elements, but we'd like to try it anyway for the sake of this project.

We could do it with an H-bridge for each one of the elements, but that would take a lot of work and components. I was thinking that we might be able to simplify it. Would it be possible to use four relays to reverse polarity on the power supply side, and then connect the peltier elements with optocouplers or something to do the pulse width modulation? That way, for each heating element we only need one component (which we open and close from an Arduino with a shift register), instead of a whole H-bridge module or four mosfets for each.

Which component would be a good fit if we want to send 12V @ 1 amps (peak 3 amps) through it? At first I thought a MOSFET like IRLZ44N would work, but they only work in one direction I think, with the source connected to ground. Would something like the TLP175A enable us to PWM the elements even when the direction of the current reverses?

Thanks for any advice!

EDIT

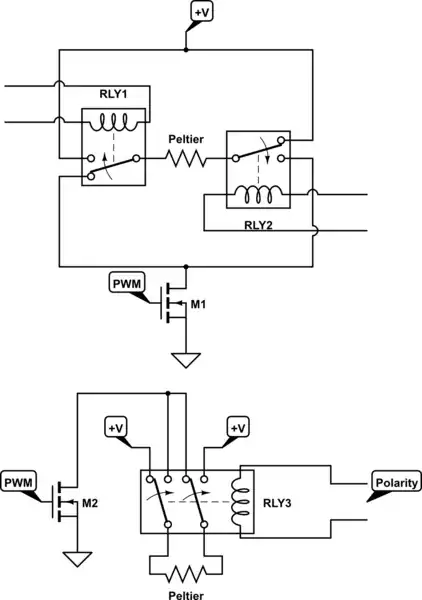

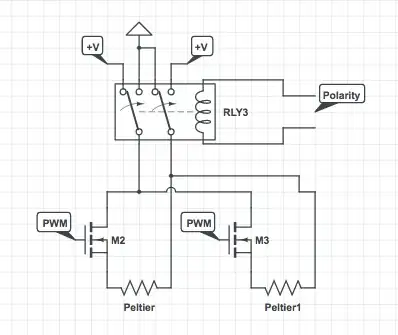

So I was thinking of something like this:

But this has the problem that the MOSFETS will not work with the current in both directions. So I was thinking there would be an alternative component that would.