The answer depends significantly on the desired test time.

Is it minutes to hours or days to weeks or months.

In the case of tests lasting less than a few hours a "lashup" of a small chamber with temporary materials will probably suffice.

If test times in the days to months are required then a more permanent construction is needed.

You need to decide what you are attempting to test for and whether all the parameters are relevant to all components. For instance, while solar insolation may drive temperature and humidity, it is unlikely that the electronic internals of a device are greatly or at all affected by the UV (ultraviolet) content of sunlight. It may be reasonable to test the enclosure in a sun simulating environment with an emphasis on UV exposure and the internals with an emphasis on temperature and humidity.

For tests lasting for hours where my presence in the "test chamber" was desirable I have occasionally repurposed one of the "smallest rooms in the house" with a fan heater and thermostatic control. I did not require humidity control, but humidity could be controlled using either a dehumidifier inside the controlled space (possibly problematic functionally and wrt room available), or by blowing in a low volume quantity of dried air (from a dehumidifier or other air source) that adequately dominates overall moisture content. As relative humidity drops with increasing temperature the demands on input humidity are unlikely to be hard to meet.

Where a small volume controlled space was required I have used benchtop "fan ovens" with thermostatic control. These are usually glass, allowing ease of visual checking, and have a lift off lid, allowing ease of access.

Warning: Remove chicken and other foodstuffs before adding PCBas.

For longer term and/or larger devices it will be "easy enough" to construct or repurpose a structure of suitable size with eg "chipboard" construction.

A glass or other transparent material door is not essential but makes life easier.

Uniformity of heat distribution should not be a great issue with modest air circulation.

A PID controller could be used for temperature and humidity control but in many cases simple thermostat and linear humidity control (admit more dryer air at a suitable rate as required) should be adequate.

A UV source could be added at the top of the chamber to model solar effects if desired.

Heating elements at the top could be used if differential heating modelling was required.

It may make sense to repurpose a "toaster over" or even a full size oven

Don't the fans just circulate the hot ambient air?

Yes, but ... .

Temperature transfer from a convecting surface to ambient air is greatly assisted by air flow. So flowing air tends to drive the device temperature towards ambient, while still air transfers heat away with the device exceeding ambient to cause this to happen. Radiation may or may not be a significant factor.

So It deep-ends what the intention of the chamber is.

If it's to keep electronics at a steady state long term test temperature then air flow helps this. If it's to see how well a device performs inside a housing at a given temperature then air flow may produce conditions which do not match reality.

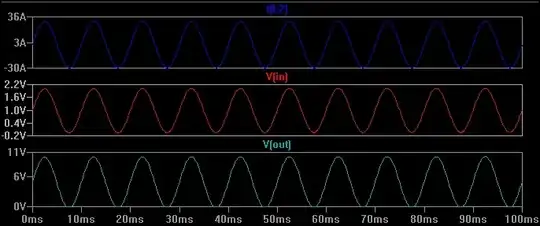

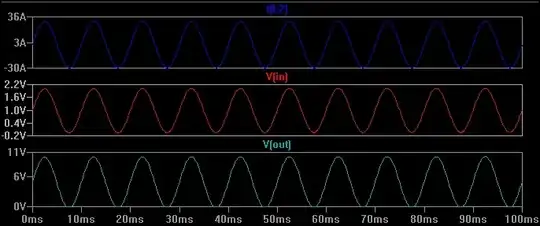

I had an application (http :// bit.ly/SL2MINIAFRICA)* where I needed to test the performance of a charge circuitry AND the batteries being charged inside a sealed plastic container. The batteries did not generate significant heat for most of the charge cycle. The batteries were often maintained at high temperatures due to ambient conditions external to the device.

* Scroll, don't click. x00,000 .

Heating the batteries with moderate air flow seemed to meet the need adequately. Heating the electronics was not so crucial in this case as failure at temperature was not an issue here and was not being tested and performance at temperature was separately assessed initially.