Im no expert on the subject but I've done some simple PCBs so here's my two cents

1) Don't route 90 degree angles

Why is there such a strong preference for 45 degree angles in PCB routing?

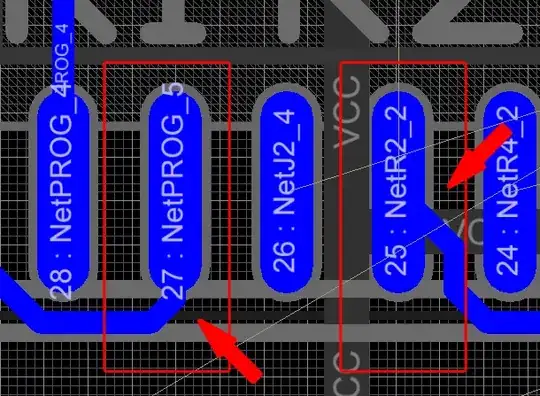

2) Make sure your silkscreens are going to be visible when the components are populated. Once R5 is populated, R2's silkscreen is covered.

3) Also make sure there is enough useful information on the silkscreen as well. You'll probably be able to make out the line on the diode part outline but may be a good idea to add a "+" to the positive side of the diode, offset from the bottom of it. This may be opinionated since the square pad does the same but I think it's a good practice in case it were an SMD diode. Same with the connectors. Add a positive indicator so you know which pin is positive. Sure you can flip the board, but say you end up mounting this to something and cant access the bottom, it wont be so easy to tell. Switches with more than 2 pins, add a silkscreen showing where pin 1 is. And then on the second row show where pin 4 is since it could be either on the right or left.

4) Change "SW2" to "SW1". When I see "SW2" I will assume that's the second switch on the board. Also U1.B, again makes me think there should be a U1.A.

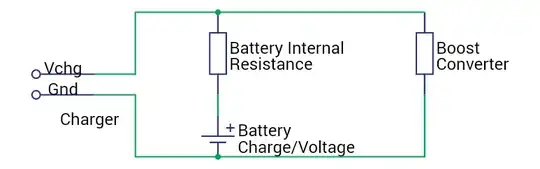

5) Make the bottom layer a ground plane.

What are the advantages of having two ground pours?

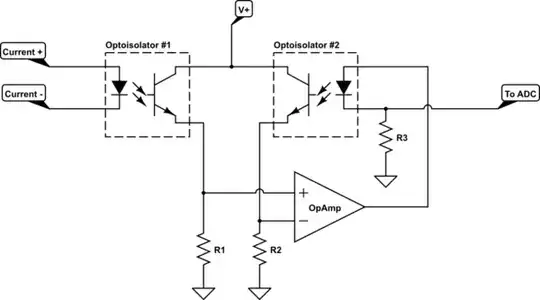

6) I don't know what U1.B is, but maybe read the datasheet again. I suspect it might suggest adding a bypass cap across the power input

http://www.learningaboutelectronics.com/Articles/What-is-a-bypass-capacitor.html

EDIT: Also, why use a DPDT switch? Overkill for your application