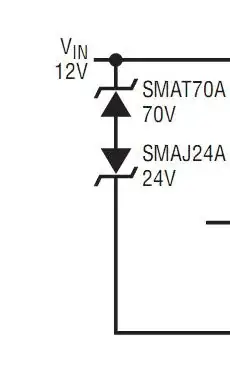

I often see two zeners (in opposition to each other) being placed across the power supply rails. I don't understand why that is necessary.

For example, if I have a 16V Zener diode and a 12V power rail, the 16V Zener will protect the supply from transients above 16V. It will also prevent negative transients below -0.7V - say, if i reversed the battery.

Why would placing two zeners in opposition improve this. Say if I placed two 15V Zeners in the same setup. It will now protect the supply from transients above ~16V (which is fine). but it now will only protect the supply from negative transients below -16V instead of -0.7V. Why would anyone want this? I don't want the supply rail to go to the negative at any stage!

For example: see example circuits in http://cds.linear.com/docs/Datasheet/4359f.pdf